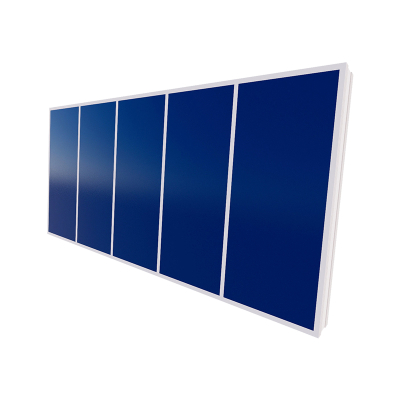

Vacuum Heat Pipe Collector

1. Fully Enclosed Flow Channel Design: Dual Protection of Durability and Safety

2. Superconducting Metal Heat Pipe: Enables Efficient and Rapid Heat Exchange

3. Pressure-Bearing Operation Structure: Ensures Stable Energy Supply 24/7 All Year Round

4. Customized Design: Achieves Integrated Integration of Buildings and Energy Systems

High-Efficiency Solar Thermal Solution for Commercial and Industrial Hot Water Applications

By Soletks Solar

Against the backdrop of the global transition toward clean, low-carbon energy systems, high-efficiency solar thermal utilization technologies are becoming a focal point of the renewable energy industry. Among them, the heat pipe solar collector stands out as a benchmark solution in the solar thermal sector. By integrating specially designed heat pipes and utilizing the phase-change cycle of a working fluid—vaporization and condensation—it achieves ultra-fast and highly efficient heat transfer.

This fundamental working principle allows the heat pipe collector to overcome the long-standing limitations of conventional solar collectors, such as low thermal efficiency, unstable operation under harsh climates, and weak anti-interference capability. As a result, it is now widely recognized as a preferred green thermal energy solution for commercial buildings, industrial processes, and public utility facilities.

1. Wide Application Coverage for Centralized Hot Water Demand

Thanks to its stable operating performance and flexible installation methods, the heat pipe solar collector is perfectly suited for all types of medium- and large-scale centralized hot water systems. It has been extensively deployed in:

· Hotels and resorts

· Schools and universities

· Hospitals and medical centers

· Public swimming pools

· Dormitories, sports centers, and commercial complexes

It ensures 24-hour stable hot water supply for hotel guest rooms, supports high-frequency centralized water usage in campuses, guarantees medical-grade sanitary hot water in hospitals, and provides constant-temperature heating for swimming pools. For any scenario with continuous and intensive hot water demand, the heat pipe solar collector delivers reliable, sustainable, and cost-efficient thermal energy.

2. Four Core Advantages That Fundamentally Redefine Solar Thermal Performance

2.1 Fully Sealed Heat Transfer Channel

Durability and Safety in One Structure

Traditional solar collectors often suffer from water leakage, internal corrosion, and seal aging due to imperfect sealing technologies. In contrast, the heat pipe solar collector adopts a completely sealed heat transfer system, effectively isolating moisture, oxygen, and contaminants.

This design ensures:

· Zero water leakage risk

· Excellent corrosion resistance

· Service life exceeding 15 years, significantly longer than the typical 8–10 years of conventional collectors

· Substantially reduced maintenance and lifecycle cost

2.2 Super-Conductive Metal Heat Pipe

High-Speed, High-Efficiency Heat Exchange

The super-conductive metal heat pipe serves as the “power core” of the system. Heat is transmitted through a phase-change process, rather than solid-state conduction, enabling:

· Heat transfer speed dozens of times faster than traditional metal conductors

· System thermal efficiency exceeding 80% under strong solar radiation

· 10%–20% higher efficiency compared with conventional vacuum tube collectors

· Ultra-fast 5-second thermal response, instead of several minutes of preheating time

Even under weak sunlight, winter conditions, or cloudy weather, the system can still collect and deliver heat effectively.

2.3 Pressurized Operation Structure

All-Season, All-Weather Stable Energy Supply

The heat pipe collector adopts a unique “no water inside the evacuated tube” design. Only special heat transfer working fluid is sealed inside the heat pipe. This completely eliminates:

· Tube bursting at high summer temperatures

· Freezing and cracking during winter

The system can operate stably within an extreme temperature range from –50°C to above +40°C, without risks of leakage or freezing. This structure ensures true year-round uninterrupted heat supply, even in high-latitude cold regions.

2.4 Fully Customized Design for Building–Energy Integration

Collector dimensions and collecting areas can be custom-designed according to architectural structure and thermal demand. Installation options include:

· Roof-mounted

· Façade-mounted

· Integrated shading structures

In large commercial buildings, the collector can be integrated with photovoltaic modules to form a “PV + Thermal” hybrid energy system, achieving cascade energy utilization and maximizing overall energy efficiency.

3. Technical Specifications

Type of collector | HPC182 | HPC240 | HPC298 | HPC370 | HPC442 | |

outline dimension (mm) | 1025×1920×131 | 1325×1920×131 | 1625×1920×131 | 2000×1920×131 | 2375×1920×131 | |

Vacuum tube specifications | φ58×1800, the outer wall thickness is 2.0mm, and the inner wall thickness is 1.6mm | |||||

fin | 3003 anti-rust aluminum, wall thickness 0.2mm, length 1620mm | |||||

Number of vacuum tubes | 12 | 16 | 20 | 25 | 30 | |

Total area (m²) | 1.82 | 2.4 | 2.98 | 3.7 | 4.42 | |

Lighting area (m²) | 1.2 | 1.6 | 2 | 2.5 | 3 | |

net weight (kg) | 42 | 55 | 67 | 85 | 99 | |

Working pressure (MPa) | 0.6MPa | |||||

Interface size | Φ 22 light tubes | |||||

Number of interfaces | Two | |||||

Total heat loss coefficient | 2.453W/(m²·K) | |||||

Maximum operating temperature (℃) | 120℃ | |||||

Peak efficiency | 0.724 | 0.724 | 0.724 | 0.724 | 0.724 | |

rated efficiency ① | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | |

specified | 400W/m² | 0.2 | 0.27 | 0.33 | 0.42 | 0.5 |

700W/m² | 0.46 | 0.61 | 0.77 | 0.96 | 1.15 | |

1000W/m² | 0.72 | 0.96 | 1.2 | 1.5 | 1.8 | |

Gas volume (L) | 0.8 | 1.04 | 1.27 | 1.57 | 1.86 | |

4. Performance Details That Define Superior Quality

· Super-conductive heat pipe thermal conductivity reaches 99%, achieving full heat transfer in just 5 seconds

· 3003 aluminum fins ensure long-term stability under humidity, salt fog, and extreme temperature conditions

· Built-in one-way thermal diode function effectively prevents reverse heat loss

· Winter heat exchange efficiency remains above 55%, far exceeding conventional 30%–40% levels

· “No-water-in-tube” design completely avoids internal scaling and freezing risks

· Reliable operation even at –50°C, ideal for alpine and high-latitude regions

5. Why Choose Soletks Solar for Heat Pipe Collectors?

Industry-Leading Core Technology

Soletks Solar holds 117 core patents and proprietary solutions. It is among the very few manufacturers capable of mass-producing both blue selective coatings and black selective coatings, with the black coating holding approximately 60% market share in China. The company operates 6 R&D platforms, 7 specialized development departments, and 1 key laboratory, forming a complete innovation ecosystem.

Complete Industrial Chain Integration

With 7 subsidiaries and 6 production bases, Soletks Solar covers the entire value chain—from core materials to system integration. The annual production capacity of flat-plate clean thermal equipment reaches 7.0 GWth, and flat-plate collector output has ranked second globally for two consecutive years.

Advanced Intelligent Manufacturing

Highly automated production lines enable one collector to come off the line every 55 seconds, ensuring both high consistency and fast delivery.

Tailored Solutions for Global Markets

Customized solutions can be provided for:

· High-altitude extreme cold regions

· Central European heating systems

· Southeast Asian high-humidity climates

· Industrial hot water and process heat applications

6. FAQ – Heat Pipe Solar Collectors

Q1: What is a heat pipe solar collector?

A heat pipe solar collector is a solar thermal device that combines evacuated glass tubes with sealed copper heat pipes. It transfers solar heat to the working fluid with extremely high efficiency, fast response speed, and strong low-temperature adaptability.

Q2: How does the heat pipe work?

A fixed amount of phase-change working fluid is sealed inside the heat pipe. After absorbing solar heat, it rapidly evaporates and rises to the condenser section, where it releases heat to the circulating water. The vapor then condenses and flows back by gravity to repeat the cycle.

Q3: What are the advantages over flat-plate collectors?

Heat pipe collectors perform better under low-light and low-temperature conditions, start faster, and benefit from vacuum insulation that dramatically reduces heat loss—making them ideal for cold climates and industrial systems.

Q4: Can they operate continuously all year?

Yes. The vacuum insulation structure and antifreeze working fluid allow stable operation below freezing, enabling true all-season performance.

Q5: What maintenance is required?

Maintenance is minimal: periodic inspection of piping and seals, surface cleaning of glass tubes, and an annual performance check of heat exchange components.

Contact

Shandong Soletks Solar Technology Co., Ltd

Brand: Soletks Solar

Email: export@soletksolar.com