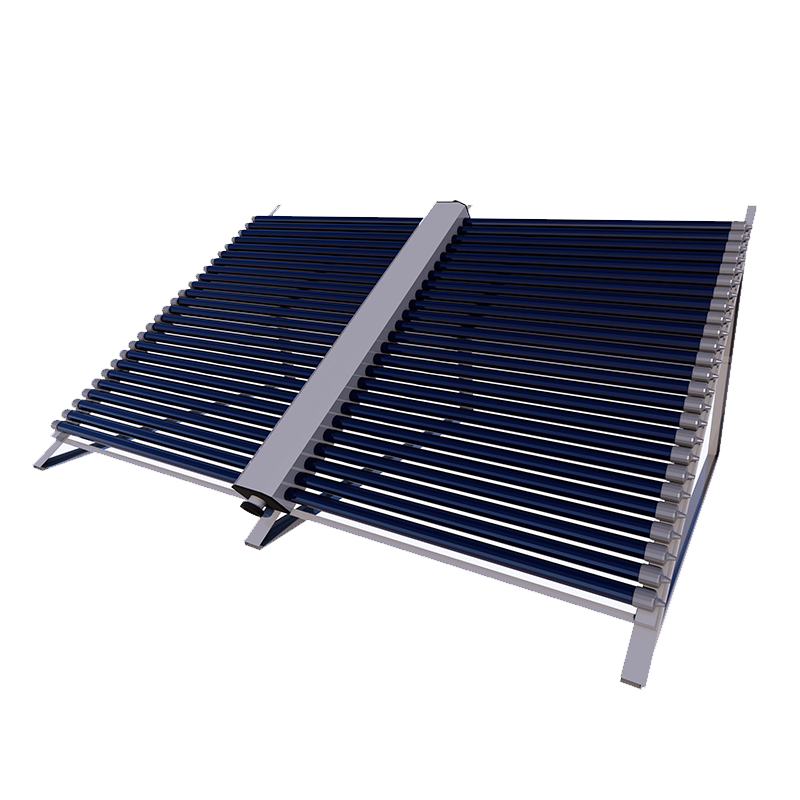

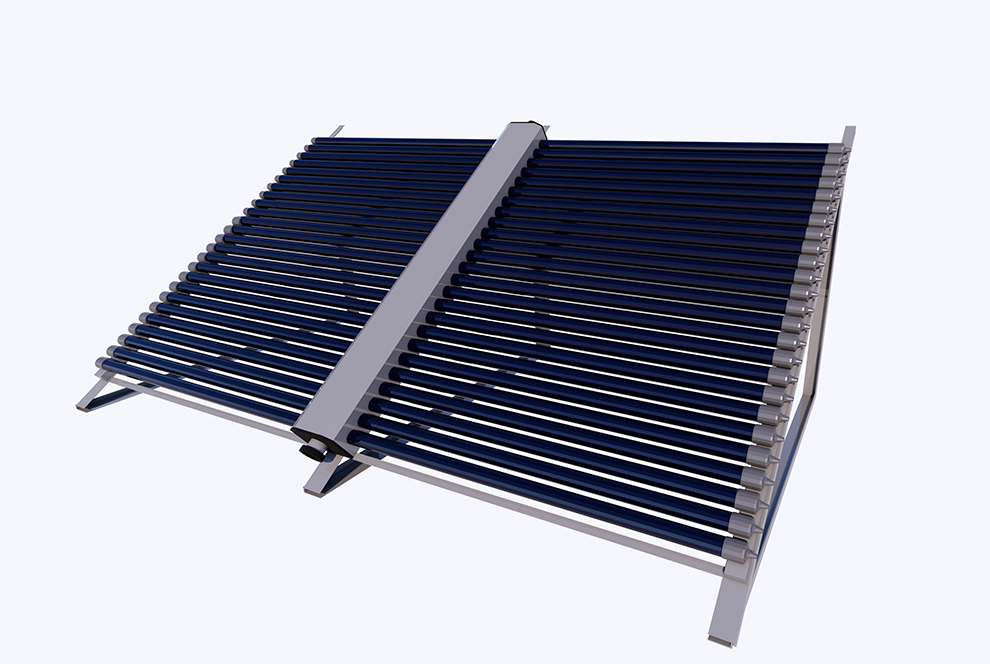

Heat Pipe Solar Collector

1. Choose high quality and high efficiency all-glass vacuum solar collector tube, with uniform film color, resistance to hot and cold shocks, and long service life.

2. The inner liner adopts docking double-sided argon gas protection welding process, longer service life;

3. The inner liner port adopts bite-free welding technology, high-temperature sealing, avoiding end cap leakage;

4. German technology fluorine-free polyurethane foam insulation, foam uniformity, good insulation effect.

It is a high-performance solar thermal solution specifically engineered for large-scale hot water applications in residential, commercial, and industrial settings. This innovative collector directly heats water and integrates with a large-capacity storage tank to form a closed-loop circulation system, significantly enhancing energy utilization and thermal efficiency.

Thanks to its plug-in design, installation is fast, straightforward, and cost-effective. Unlike traditional systems that require complex piping or intermediate heat exchangers, the Plug-in Solar Collector facilitates direct water heating, ensuring maximum heat transfer efficiency with minimal investment.

Whether you're developing a solar hot water system for hotels, schools, hospitals, or factory dormitories, this type of collector offers reliable performance, seamless integration, and extended service life. It is particularly well-suited for areas with high hot water demand and a focus on reducing energy costs and carbon emissions.

Application Scenario:

Widely used in hotels, guesthouses, schools, hospitals, parks commercial hot water supply, industrial heat, district heating and other scenes.

UHS Encapsulation Technology:

Addressing industry leakage issues, the adoption of butt welding, despite its complexity and higher argon gas costs, results in superior quality. Utilizing double-sided argon gas welding and port occlusion-free welding technology, the joint box exhibits excellent pressure resistance and corrosion resistance, with weld life extending up to 15 years.

1.360°seamless connection

The inner liner adopts butt joint double-sided argon gas shielding welding, with better pressure bearing and durability.

2. Independent end cap welding-free sealing technology

Independent research and development of welding-free technology, port corrosion resistance, protection performance is more prominent.

3. Strong pressure-bearing, weld life of up to 15 years

The inner liner can withstand a test pressure of 1.0MPa, which is 16 times of the working pressure standard stipulated by the national standard.

Company Strength:

The company has partnered with seven leading research institutions, including the Chinese Academy of Sciences, Tsinghua University, and the Shandong Academy of Sciences, to promote the transformation of solar energy from traditional “hot water” applications to advanced “flat-plate clean thermal energy.” We have established seven R&D departments, one research institute, one academician workstation, one laboratory, and one thermal energy institute. With an annual output of 7.0 GWth of flat-plate clean thermal energy equipment, the company ranks second globally in flat-plate collector production. We possess core technology and a dedicated production line for solar spectrum selective absorption coatings, holding the top market share in core materials across the industry.

The company has been recognized as a National High-Tech Enterprise, a “Specialized and New” Enterprise in Shandong Province, a Shandong Gazelle Enterprise, and has received distinctions such as the Shandong Academician Workstation and Shandong Enterprise Technology Center.

International Projects:

Domestic Projects: