Amid global energy transition and the "dual carbon" goals, solar thermal technology has emerged as a game-changer for district heating and industrial/agricultural heat solutions. EFPC's high-efficiency integrated flat-plate collectors, flagship products of SOLETKS Group, have become the go-to equipment for clean heating systems. Their proven efficiency, reliability, and cost-effectiveness deliver green solutions for diverse thermal demands.

Core strengths are prominent, and multi-scenario value is leading

The core competitiveness of EFPC's high-efficiency integrated large flat plate collector lies in its outstanding performance metrics and exceptional economic and environmental benefits. Whether for residential heating in high-cold, high-latitude regions or industrial/agricultural heat applications with stringent requirements, it delivers maximum value.

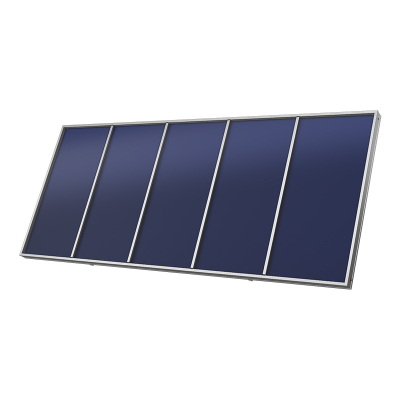

In the field of residential heating, the product demonstrates strong environmental adaptability. A single unit has a contour lighting area of up to 15㎡, and even under harsh conditions with a temperature difference between working and ambient temperatures exceeding 70℃, its output efficiency remains stable at over 55%, perfectly meeting the district heating demands of high-altitude and high-latitude regions in western areas such as Xizang, Qinghai, and Xinjiang. The heating system using this product can reduce initial investment costs by over 30%, lower operating costs by more than 60% compared to traditional coal-fired heating, and achieve a carbon emission reduction of over 70%, achieving dual improvements in economic and ecological benefits.

The product also performs excellently in industrial and agricultural heat applications. When operating at 90°C, it maintains a photothermal conversion efficiency above 45%, reliably supplying continuous heat for processes like textile dyeing, industrial preheating, copper ore cleaning, and agricultural product processing disinfection, meeting the stringent heat requirements of industrial production.

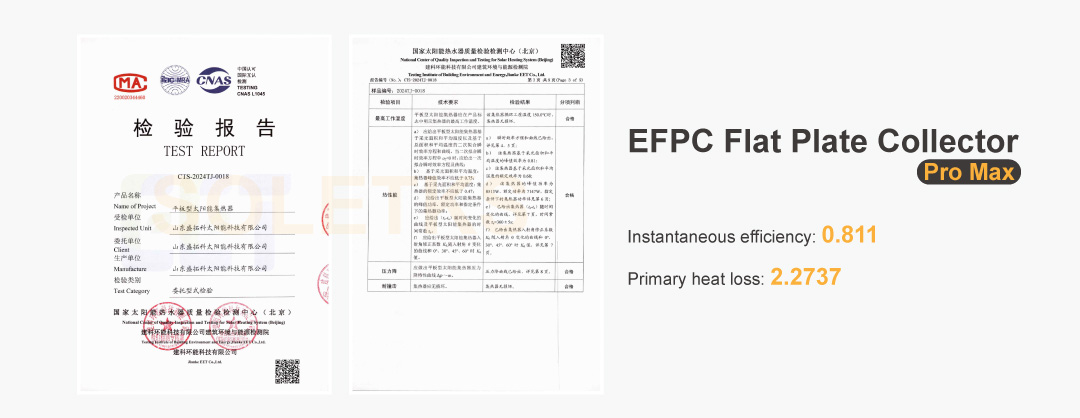

In terms of basic performance, the product has a peak efficiency of 0.8, a rated efficiency of 0.6, an effective light collection area of 13.95 m² per unit, a rated output power of 9 kW, a peak power of no less than 11.3kW, and a flow channel pressure resistance of 1.05 MPa. All these indicators are at the leading level in the industry. Additionally, compared to ordinary flat plate collectors, its heat collection efficiency is increased by 30%, with higher design pressure, larger single-unit area, and significantly fewer connection points, ensuring better system stability. Coupled with HTC's patented quick-connect technology, manual operation can meet the pressure resistance standards, and after unloading, it only takes 5 minutes to install a single unit, reducing the construction period by 80%, greatly lowering the time and labor costs of installation, and correspondingly reducing the consumption of auxiliary materials.

Four major technological innovations, solidify the foundation of performance

High-transmittance anti-reflective cover plate technology: Through simulation design of multi-layer anti-reflective film system, vacuum magnetron sputtering process is adopted to deposit, which can increase the light transmittance of ultra-white cloth-textured tempered glass by 3%~5%, and the maximum can reach 95%, laying the foundation for high-efficiency photothermal conversion.

High-temperature resistant cover plate sealing process: Using high-temperature resistant sealant and fully automatic sealing technology, the composition of the sealant layer is optimized to enhance temperature resistance and reliability, fundamentally preventing seal failure and harmful substance release in high-temperature environments.

High-pressure-resistant and low-flow-resistance integrated flow channels: By integrating CAD and CFD simulation technologies to optimize the flow channel structure, high-absorption coating materials are selected, and multiple small flow channel layouts are designed. This design enhances heat collection efficiency while achieving dual advantages of high pressure resistance and low flow resistance, with the flow channel pressure resistance reaching 1.05MPa.

Heat-bridge-free truss structure: By employing specialized construction and material configurations to block thermal conduction, this framework utilizes lightweight, high-strength, and low-thermal-conductivity materials. It effectively prevents the heat bridge effect, minimizes heat loss, and further enhances system energy efficiency.

Collector type | EFPC115 | EFPC150 | |

outline dimension (mm) | 5030×2270×140 | 5960×2520×166 | |

Surface area (m²) | 11.42 | 15 | |

Lighting area (m²) | 10.48 | 13.92 | |

net weight (kg) | 235 | 315 | |

Working pressure (MPa) | 1.0MPa | ||

Interface size/number | HTC40 quick connector | ||

Number of interfaces | Two | ||

Maximum operating temperature (℃) | 150 | 150 | |

Peak efficiency | 0.79 | 0.81 | |

rated efficiency ① | 0.66 | 0.68 | |

peak power (KW) | 8.28 | 11.26 | |

specified power (kW)② | 400W/m² | 1.7 | 2.03 |

700W/m² | 4.3 | 5.84 | |

1000W/m² | 6.85 | 9.4 | |

displacement volume (L) | 11.5 | 13.8 | |

pressure drop | 2kPa@0.22kg/(m²·s) | ||

Installation point | Four | ||

Market application and implementation, western promotion effect is remarkable

With its robust product capabilities, the EFPC high-efficiency integrated large flat plate collector has been widely validated in practical scenarios. Since 2020, western regions represented by Xizang, Qinghai, and Xinjiang have gradually promoted the application of district heating projects based on this product, providing clean and stable heating services for local residents, effectively replacing traditional fossil fuel heating, and contributing to the energy structure upgrade and ecological environmental protection in western regions.

Enterprise strength escort, technology innovation continues to lead

The iterative product upgrades and market expansion of SOLETKS Group are underpinned by its profound technological expertise and strategic industrial layout. As a new energy enterprise specializing in core technologies for flat-plate solar collectors, the group holds multiple proprietary intellectual property rights in key areas including: magnetron sputtering fabrication of high-weather-resistant selective absorption coatings (blue film), BONDING heat transfer technology, high-temperature selective absorption coating production, and phase change material (PCM) thermal storage systems.

The group has successfully developed China's first fully automated magnetron sputtering high-weather-resistant coating production line, accumulating extensive practical experience across key stages of large-area magnetron sputtering technology, including film system development, vacuum coating equipment R&D, installation and commissioning, process optimization, stable operation, and product testing. Leveraging its deep expertise in solar thermal utilization, the group has achieved a 73.5% compound annual growth rate for nine consecutive years, evolving into a comprehensive new energy conglomerate that integrates R&D, production, and solution provision for solar clean energy thermal applications. It delivers customized coupling solutions for diverse scenarios such as urban district heating, rural distributed heating, industrial heat demand, and agricultural facility heating.

From breakthroughs in core technologies to leading product performance, from market promotion in western regions to delivering full-scenario solutions, EFPC's high-efficiency integrated large flat-panel collectors are becoming a significant force in driving the industrialization of solar thermal utilization with their strong comprehensive advantages, contributing China technology and China solutions to the global clean energy transition.