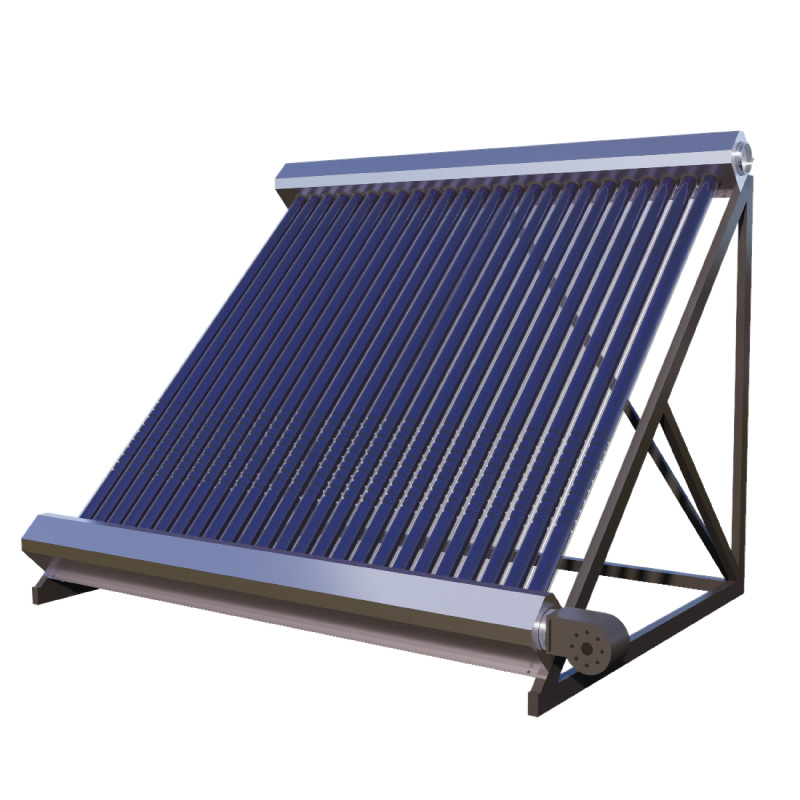

DVC500 Solar Air Collector

· Eliminates traditional solar system vulnerabilities such as tube bursting, freezing, and leakage

· Very high energy conversion efficiency, reducing long-term energy expenditures

· Exceptional durability, with service life reaching 50+ years

· Effective in every climate, from tropical highlands to sub-zero winters

· Wide application coverage, supporting heating, ventilation, drying, and hybrid heat pump systems

· Low maintenance requirements, especially useful for rural or remote installations

1. Product Overview: Redefining Solar Air Heating Technology

The DVC Solar Air Collector represents an advanced evolution in solar thermal engineering, designed to replace conventional liquid-based systems with a pure air-circulation heating method. By removing water and glycol entirely from the system, the DVC collector eliminates risks such as freezing, leakage, corrosion, scaling, and pressure-related failures—issues that have challenged traditional solar systems for decades.

At the heart of the DVC design is a direct-flow, double-pass vacuum tube combined with high-precision selective coating and an internally engineered expansion structure. These elements work together to ensure smooth airflow, reduce internal stress, and maintain durability across extreme temperature variations. As a result, the DVC system offers a clean, safe, and long-life solution for building heating, agricultural drying, industrial air heating, storage facilities, and remote-area heat supply.

Unlike water-based collectors that require complex piping and continuous antifreeze protection, the DVC solar air heater warms air directly inside its vacuum tubes, sending heated air into the indoor environment or drying chamber. This design leads to rapid heat delivery, strong airflow stability, minimal maintenance, and outstanding energy efficiency—making it a superior option for cold climates, high-altitude regions, and applications demanding continuous high-temperature operation.

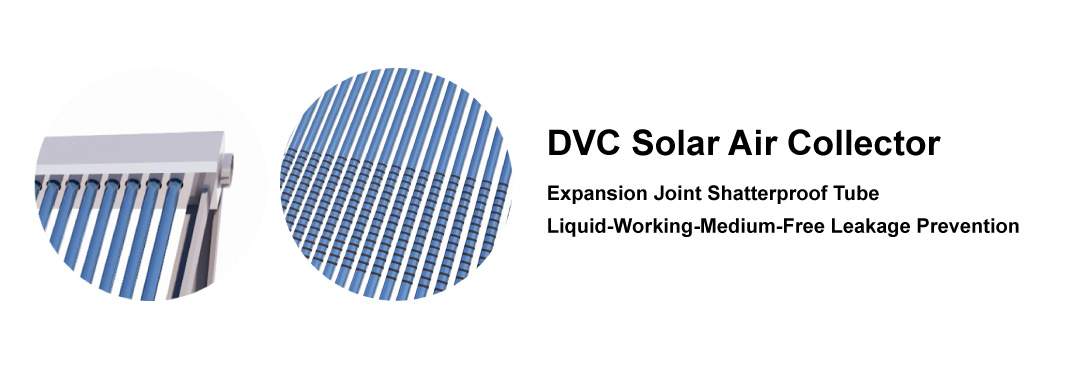

2. Product Features: DVC 500 Dual-Flow Vacuum Tube Solar Air Collector

1) Breakthrough Design: Air Medium for Enhanced System Safety

Air as the working medium

The DVC system uses air, a naturally safe and stable medium, for heat transfer. Since no fluid circulates within the tubes, there is no risk of freezing, boiling, rusting, or fluid loss. Heated air is distributed by a circulation fan and can be used directly for space heating or coupled with an external exchanger when indirect heating is required.

Double-flow vacuum tube with minimized resistance

The engineering emphasis lies in the front-to-rear open channel inside the vacuum tube, enabling air to pass freely through the tube’s core. This straight-through airflow path dramatically reduces friction and pressure loss. Reduced resistance means higher air volume at the same fan power, better thermal exchange, and increased system output.

The integrated expansion-joint section manages temperature fluctuations, absorbing thermal stress and preventing glass damage—an essential feature for cold regions or systems experiencing rapid heating cycles.

2) High-Performance Coating: Maximizing Solar Absorption

Every DVC vacuum tube is coated using a magnetron sputtering selective layer, optimized through interference technology. This enables:

· Solar absorptance of 93% ± 2%

· Thermal emittance of 6% ± 2% at 80°C

This selective coating ensures highly efficient solar capture while minimizing radiative heat loss, securing strong thermal performance even under sub-optimal conditions such as cloudy weather, winter sunlight, or high-altitude environments. The system consistently achieves solar-to-heat conversion efficiencies above 80%, placing it within the top tier of solar air heating technologies.

3) Designed for Harsh Environments: Long Life and High Reliability

Handling extreme temperatures

The tubes can operate safely at temperatures exceeding 280°C, providing an advantage for demanding applications such as industrial or agricultural drying. Because air does not freeze or expand under cold conditions, the system operates smoothly even when ambient temperatures plunge below -30°C.

Mechanical protection and durability

The expansion-joint structure mitigates thermal shock, preventing fractures caused by sudden temperature changes. The absence of liquids also removes concerns about corrosion, leaks, or internal scaling. These design choices result in a system that offers 50 years or more of service life, with little to no maintenance required.

4) Hybrid Integration with Heat Pumps: Superior Winter Performance

In cold regions, heat pumps often suffer from reduced efficiency due to low air-source temperatures. When combined with a DVC solar air collector, the heat pump receives preheated intake air, enabling:

· Improved COP in sub-zero environments

· Reduced frosting cycles

· Lower power consumption

· More stable thermal output throughout the winter season

This hybrid solar-plus-heat-pump solution ensures reliable heating even in climates with long, harsh winters.

3. Four Key Advantages: Building a Solid Competitive Foundation

1) Dual-Pass Tube with High Airflow Capacity

The DVC’s streamlined air channel lowers internal air resistance by more than 30% compared with typical solar air heaters. With improved airflow efficiency, the collector delivers:

· Faster warm-up times

· More uniform indoor heating

· Stronger performance for long-distance air distribution

· Less dust accumulation inside the tube

This design improves overall thermal stability and enhances occupant comfort in heated spaces.

2) Elevated Thermal Efficiency for Reduced Operating Costs

The combination of vacuum insulation, selective coating, and optimized tube geometry results in highly efficient heat capture. Thermal efficiencies above 80% significantly outperform many traditional collectors, enabling users to benefit from:

· Zero fuel or water costs

· Lower annual heating expenses

· Short payback periods

· Reliable energy security

For industrial clients, consistent high-temperature output directly improves production stability, product quality, and economics.

3) Universal Compatibility in Multiple Climates

The DVC collector adapts to a wide range of environmental conditions:

· High temperatures: Capable of delivering elevated outlet air temperatures for drying

· Very low temperatures: Maintains high performance without freezing risk

· Strong solar radiation: Vacuum structure maintains efficiency in high-UV areas

· High altitude: Functions effectively even with low atmospheric pressure

This versatility makes the DVC system suitable for remote villages, commercial buildings, mountainous regions, and industrial drying operations.

4) Sustainable Manufacturing and Premium Build Quality

The insulation layer surrounding the casing is produced using German constant-temperature foaming equipment that ensures uniform density and superior thermal retention. The polyurethane used is fully compliant with environmental regulations, free from harmful blowing agents, and resistant to long-term aging. The result is a product that aligns with modern green-building and sustainable-energy standards.

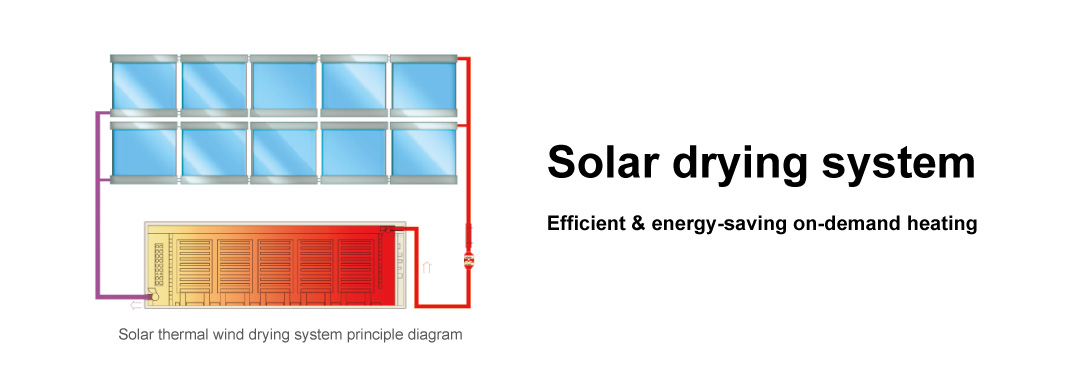

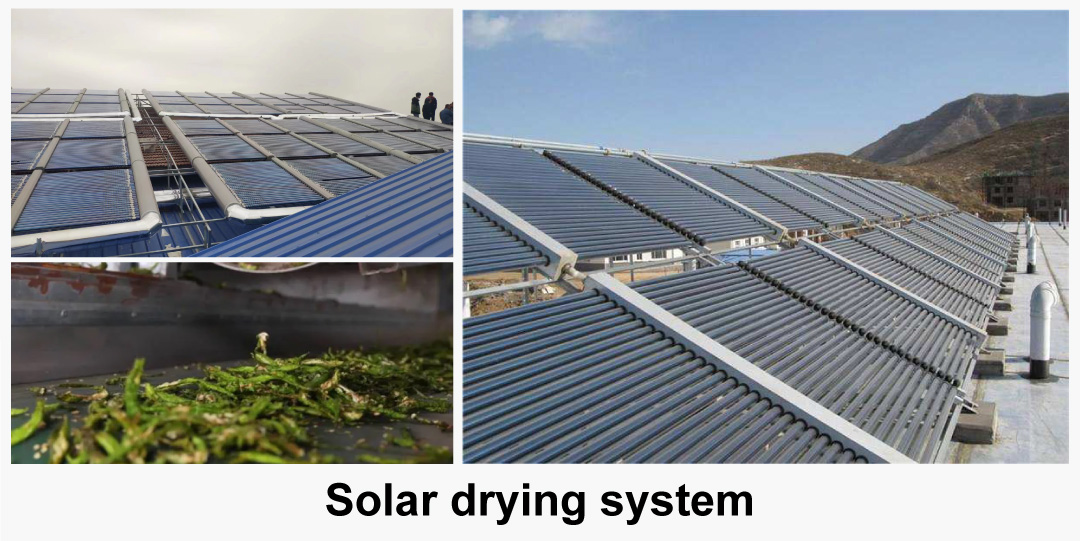

4. Application Fields: Serving Both Heating and Drying Markets

Scenario | User Needs | How DVC Provides Value |

Commercial & Institutional Heating | Heating classrooms, offices, workshops, and stations | Large air volume, quick temperature rise, stable heat distribution |

Agricultural & Industrial Drying | Drying grains, seeds, herbs, fruits, construction materials | Clean high-temperature airflow, up to 280°C, no contamination |

Cold Regions & High-Altitude Heating | Residential heating, district heating support, commercial building heating | Solar-plus-heat-pump compatibility ensures winter performance |

The DVC system covers a broad spectrum of applications, offering both ecological benefits and economic advantages to users in multiple industries.

5. Why the DVC Air Collector Stands Out

· Eliminates traditional solar system vulnerabilities such as tube bursting, freezing, and leakage

· Very high energy conversion efficiency, reducing long-term energy expenditures

· Exceptional durability, with service life reaching 50+ years

· Effective in every climate, from tropical highlands to sub-zero winters

· Wide application coverage, supporting heating, ventilation, drying, and hybrid heat pump systems

· Low maintenance requirements, especially useful for rural or remote installations

The DVC Solar Air Collector offers a forward-thinking solution for sustainable heating and drying. By combining engineering reliability with environmental responsibility, it provides long-term value for buildings, industries, and agricultural operations pursuing low-carbon energy strategies.

Collector type | DVC500 | DVC850 | |

outline dimension (mm) | 2430×2100×200 | 4030×2100×200 | |

Specification of double conduit | Φ58×1800 | Φ58×1800 | |

Number of dual pipes | 30 | 50 | |

Total area (m²) | 5.1 | 8.5 | |

Lighting area (m²) | 3.8 | 6.3 | |

net weight (kg) | 75 | 125 | |

Rated air volume (m³/h) | 150 | 250 | |

Interface size | |||

Number of interfaces | |||

Total heat loss coefficient | |||

maximum working temperature | 0.76 | 0.76 | |

Peak efficiency | 0.66 | 0.66 | |

rated efficiency ① | 2.5 | 4.2 | |

specified | 400W/m² | 0.76 | 1.62 |

power (kW)② | 700W/m² | 1.25 | 2.69 |

1000W/m² | 2.5 | 4.2 | |

6. Soletks Group: Strength Behind the Innovation

1) Cutting-Edge R&D Platform

· Holder of 117+ patents related to solar thermal design

· Advanced coating technologies including proprietary BlueCore and black-film coatings

· Development capabilities covering collectors, industrial systems, and smart control solutions

2) Advanced Manufacturing Infrastructure

· Six intelligent manufacturing centers

· High-speed automated lines capable of producing one collector every 55 seconds

· Strict quality assurance procedures across every step of the production cycle

· CE-certified products ready for global markets

3) Fully Integrated Industrial Chain

· Complete control over absorber coatings, vacuum tubes, metal components, and insulation systems

· Engineering teams capable of designing end-to-end solar thermal solutions

· Applications spanning 30+ sectors, including commercial buildings, agriculture, and manufacturing

4) Proven Global Market Recognition

· Among the world’s leading manufacturers of flat plate and vacuum solar collectors

· Products exported to 40+ countries and regions

· CO₂ emissions reduced by 16.7 million tons, supporting global carbon-neutrality efforts

· Recognized as a national benchmark in solar thermal performance and innovation

Contact Information

For quotations, project collaboration, or distributor inquiries, contact:

Email: export@soletksolar.com

Website: www.soletksolar.com

Headquarters: Soletks Group, China