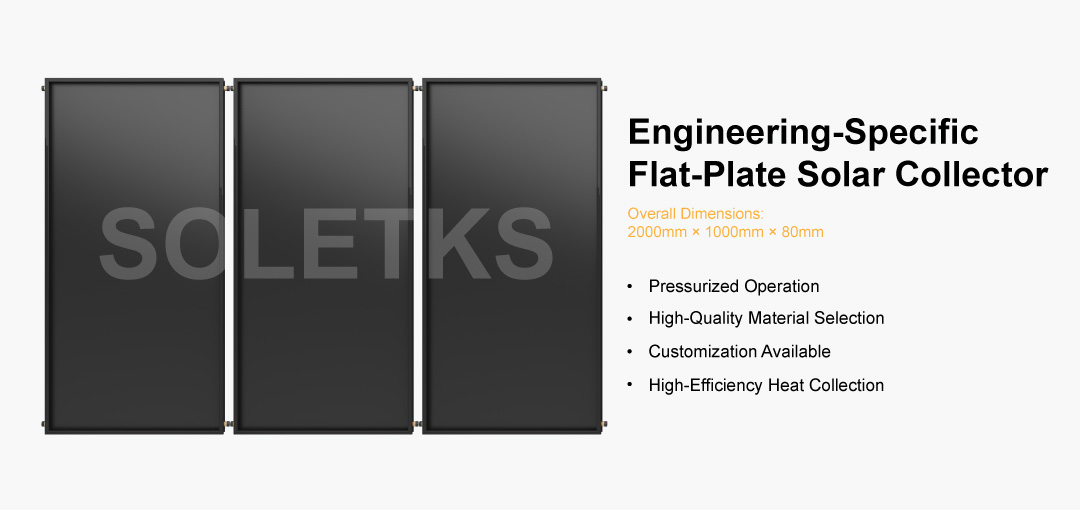

Engineering Specific Flat Plate Collector

Reliable Pressure-bearing: Engineering-grade pressure-bearing design, withstanding high pressure and preventing leakage to ensure stable system energy supply.

Strong Durability: High-quality materials for corrosion and aging resistance, adapting to long-term continuous engineering working conditions.

Flexible Customization: Configurable according to heating area, hot water volume, etc., suitable for projects of various scales.

Efficient Heat Exchange: Optimized design maximizes solar energy absorption, reducing project energy consumption.

Easy Installation: Supports series/parallel connection of multiple units, simple process saving construction period and labor cost.

Enterprise Guarantee: International certifications + strong R&D capability, products sold globally with solid technical support.

I. Product Introduction

The engineering-specific flat plate collector is a core thermal energy device tailored for large-scale centralized hot water supply and heating projects. Its design fully meets the needs of large-scale applications in the engineering field, supporting flexible series combination of multiple units. Based on core parameters such as the project's actual hot water demand and heating coverage area, the number of collectors can be accurately customized to easily match the engineering scale of different scenarios including large residential districts, schools, hospitals, factories, and greenhouses.

Combining practicality and economy, the collector is constructed with engineering-grade high-quality materials and mature craftsmanship. It not only features controllable costs and outstanding cost-effectiveness but also offers easy installation, which can significantly shorten the on-site construction cycle and reduce labor input costs. Meanwhile, its robust structural design ensures excellent corrosion resistance and aging resistance, enabling it to adapt to the engineering environment of long-term continuous operation with a long service life and low subsequent maintenance costs, providing a stable, efficient, and worry-free thermal energy solution for projects.

II. Product Advantages

1. Reliable Pressure-Bearing Operation

Adopts an engineering-grade pressure-bearing design to meet the stable operation requirements of centralized heating and hot water supply systems. It can withstand long-term high-pressure working conditions, eliminate leakage risks, and ensure continuous thermal energy output of the system.

2. High-Quality Materials for Strong Durability

Core components are made of high-quality materials that meet engineering standards, selected through strict testing. They possess excellent resistance to corrosion, aging, and harsh environments, laying a solid foundation for the long-term stable operation of the equipment.

3. Flexible Customization for Wide Adaptability

Supports customized configuration according to actual project needs. The number and combination mode of collectors can be adjusted based on parameters such as centralized heating area, hot water supply volume, and installation space layout, perfectly matching the differentiated needs of projects of different scales.

4. Efficient Thermal Energy Conversion

Relying on optimized structural design and core technologies, it can maximize the absorption of solar energy resources, quickly realize thermal energy conversion with high heat exchange efficiency, effectively reduce project energy consumption, and improve the cost-effectiveness of energy utilization.

III. Application Scenarios

Widely applicable to various places with large-scale demands for centralized heating or hot water supply, including but not limited to large residential districts, public and private schools, general hospitals and specialized hospitals, various production factories, and agricultural greenhouses.

IV. Product Features

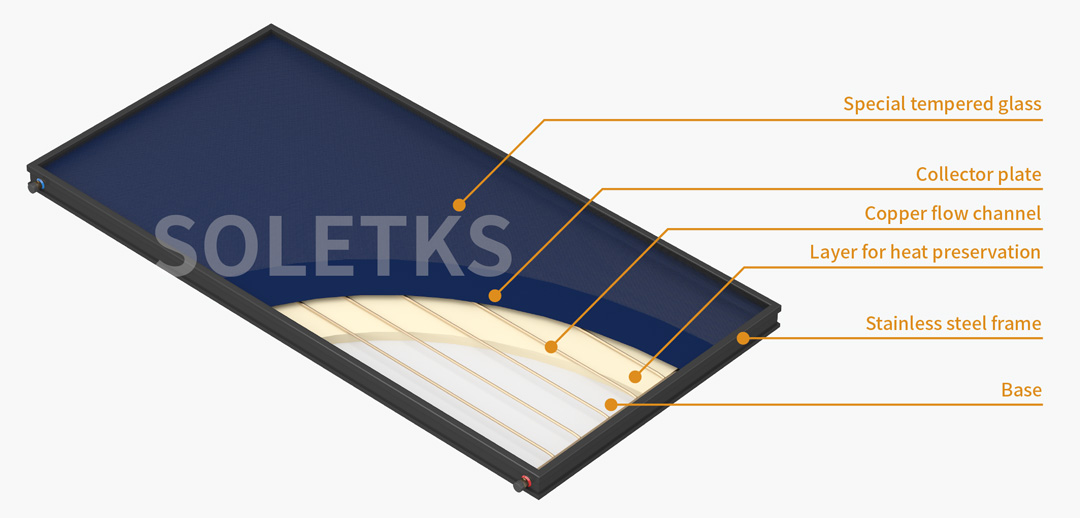

1. High-Performance Selective Absorption Coating

Adopts industry-leading high-quality selective absorption coating technology. The coating has strong adhesion and excellent thermal stability, enabling efficient absorption of solar radiation and conversion into thermal energy. It also has outstanding corrosion resistance, adapting to long-term outdoor use environments and ensuring long-lasting and stable thermal efficiency.

2. High-Quality Glass Cover Plate

Equipped with low-iron textured tempered glass as the cover plate, whose light transmittance is much higher than that of ordinary glass, allowing maximum penetration of solar rays to the absorption layer. Meanwhile, the tempered glass has high strength, impact resistance, and hail resistance, with excellent protective performance, effectively protecting internal core components from damage.

3. Insulation Cabin Design for Lower Heat Loss

Adopts an integrated sealed insulation cabin structure, filled with high-efficiency insulation materials inside. It has strong sealing performance, which can reduce heat loss during heat transmission and storage, making thermal energy conversion more efficient. Even in low-temperature environments, it can maintain stable heat exchange effect and improve energy utilization rate.

4. Simple and Labor-Saving Installation

Supports free series and parallel combination installation of multiple units. The installation process is simple and easy to understand, without complex on-site commissioning procedures. It adapts to the installation conditions of various engineering sites, significantly shortening the construction cycle, reducing labor and time costs, and improving project implementation efficiency.

V. Product Parameters

Collector Model | FPC200 | Total Heat Loss Coefficient | Total Heat Loss Coefficient | 5.4W/(㎡·K) |

Overall Dimensions (mm) | 2000x1000x80 | Maximum Operating Temperature | Maximum Operating Temperature | 100℃ |

Contour Area (㎡) | 2.0 | Peak Efficiency | Peak Efficiency | 0.78 |

Lighting Area (㎡) | 1.87 | Rated Efficiency | Rated Efficiency | 0.53 |

Net Weight (kg) | 30 | Collector Power (W) | 400W/㎡ | 80.4 |

Working Pressure (MPa) | 0.6MPa | - | 700 W/㎡ | 512.4 |

Interface Size | G3/4 External Thread | - | 1000 W/㎡ | 991.1 |

Number of Interfaces | 4 | Working Fluid Capacity (L) | Working Fluid Capacity (L) | 1.6 |

VI. Company Advantages

The company focuses on the clean thermal energy market, forming a product matrix covering a temperature range of 45℃ to 150℃ to meet the needs of different scenarios. The company's products have passed multiple international certifications such as CE and SolarKeymark, and are exported to more than 50 countries and regions including Turkey, Israel, Spain, Germany, Palestine, Puerto Rico, and Barbados, achieving a good growth trend of 65% annual increase in overseas orders.

The company has established 7 R&D departments, 1 research institute, 1 academician workstation, 1 laboratory, and 1 thermal energy research institute. It has been awarded titles such as High-Tech Enterprise, Specialized, Refined, Characteristic, and Novel "Little Giant" Enterprise, Provincial Gazelle Enterprise, Provincial Enterprise Technology Center, Provincial Academician Workstation, and Provincial Postdoctoral Innovation Practice Base.