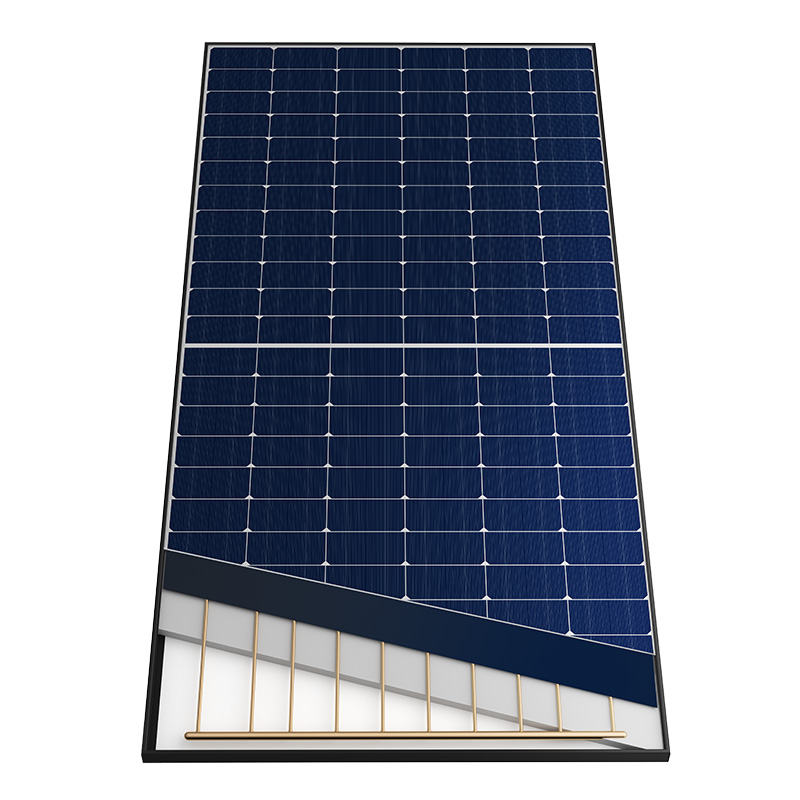

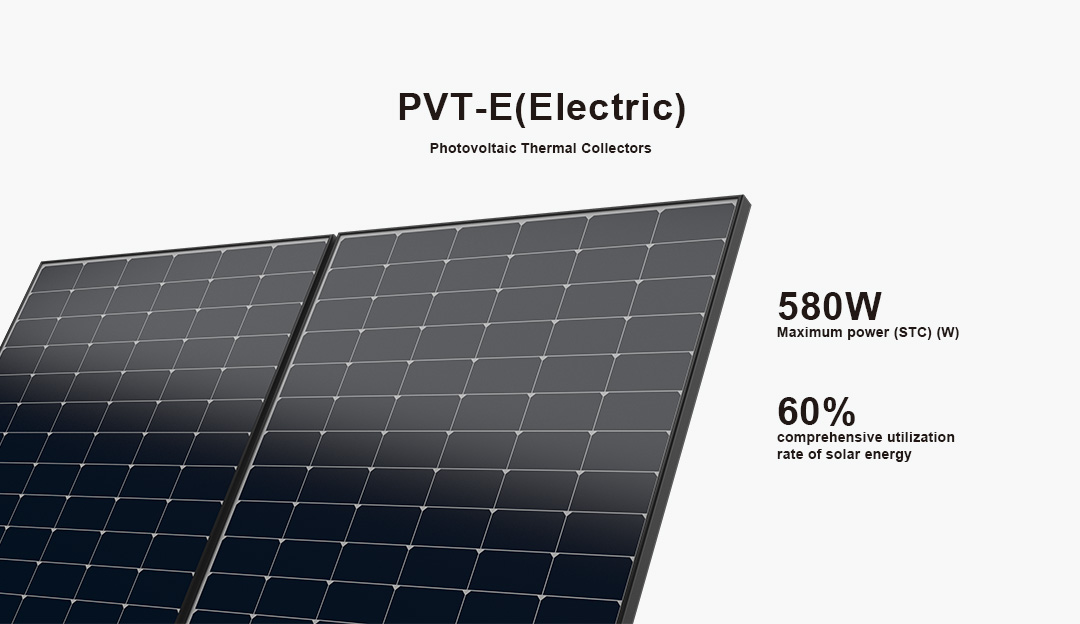

PVT-E Photovoltaic Thermal Collectors

1. Energy utilization innovation: Breaking through the limitation of traditional photovoltaic equipment in generating electricity, integrating photovoltaic and solar thermal technology to simultaneously meet the needs of electricity, hot water and heating. The comprehensive utilization rate of solar energy reaches 60%, more than 50% higher than that of traditional photovoltaic equipment, and realizing the maximum energy value.

2. Improved heat transfer efficiency: The vacuum bonding process is adopted to greatly reduce the interface thermal resistance of the module, and the thermal energy utilization efficiency is improved by more than 40%, ensuring rapid and stable heat transfer and guaranteeing efficient energy use.

3. Optimization of equipment life and efficiency: equipped with intelligent temperature control system, effectively prevent the generation of hot spots, and control the temperature difference fluctuation of components in a very small range, which not only extends the service life of equipment, but also achieves high efficiency performance of twice the thermal energy output as the electric energy.

4. Intelligent operation and maintenance cost reduction: With built-in high-precision sensors and intelligent control system, it can be seamlessly connected with the building energy management platform to dynamically adjust the heat collection power to match the energy demand, and the operation and maintenance cost is reduced by more than 35%.

With the growing demand for low-carbon buildings and efficient energy utilization, the PVT-E thermoelectric twin modules have emerged as a core solution through innovative design, integrating solar power generation and heating functions. These modules are widely applicable in building cogeneration, domestic hot water supply, and shallow geothermal coupling systems, providing integrated energy solutions across multiple sectors.

Core Performance Highlights

1. Energy utilization innovation: Breaking through the limitation of traditional photovoltaic equipment in generating electricity, integrating photovoltaic and solar thermal technology to simultaneously meet the needs of electricity, hot water and heating. The comprehensive utilization rate of solar energy reaches 60%, more than 50% higher than that of traditional photovoltaic equipment, and realizing the maximum energy value.

2. Improved heat transfer efficiency: The vacuum bonding process is adopted to greatly reduce the interface thermal resistance of the module, and the thermal energy utilization efficiency is improved by more than 40%, ensuring rapid and stable heat transfer and guaranteeing efficient energy use.

3. Optimization of equipment life and efficiency: equipped with intelligent temperature control system, effectively prevent the generation of hot spots, and control the temperature difference fluctuation of components in a very small range, which not only extends the service life of equipment, but also achieves high efficiency performance of twice the thermal energy output as the electric energy.

4. Intelligent operation and maintenance cost reduction: With built-in high-precision sensors and intelligent control system, it can be seamlessly connected with the building energy management platform to dynamically adjust the heat collection power to match the energy demand, and the operation and maintenance cost is reduced by more than 35%.

Application scenarios

The component can accurately match a variety of energy needs, including daily hot water supply for offices, constant temperature heating for public or private pools, combined heat, power and cooling systems for single buildings, and low-temperature heating for capillary networks, providing customized energy solutions for different scenarios.

Key technical support

1. High stability power generation technology: Equipped with single-crystal multi-busbar N-type TOPCon solar cells, featuring industry-leading photoelectric conversion efficiency and low peak power temperature coefficient, ensuring stable power output under varying light intensity and temperature conditions.

2. Precision temperature control design: The high-purity aluminum plate is used as the heat transfer substrate, combined with the precision channel structure, the surface temperature of the module is controlled at ±1℃, and the power generation and heat collection efficiency are improved, achieving double energy efficiency output.

3. Robust Structural Design: Featuring an anodized 6063-T5 aluminum alloy frame with 180MPa tensile strength, this equipment is equipped with high-performance weather-resistant sealant that meets IP65 waterproofing standards. It effectively resists harsh environmental conditions like sandstorms and rain, significantly reducing maintenance needs and ensuring long-term stable operation.

Technical specifications

class | Specific parameters | PVT-E Module Parameters |

Physical Specifications | outline dimension (mm) | 2279×1134×45 |

Glass size (mm) | 2273×1128 | |

weight (kg) | 39.0 | |

Electrical properties | Maximum power (STC) (W) | 580 |

Cell type | Single-crystal multi-busbar N-type TOPCon | |

Number of cells | 144(6×24)cells | |

working temperature (℃) | -40~85 | |

Maximum system voltage (V) | 1500(TUV) | |

Open circuit voltage (Voc) (V) | 51.1 | |

Maximum power point voltage (Vmp) (V) | 44.45 | |

Short-circuit current (Isc) (A) | 14.31 | |

Maximum power point current (Imp) (A) | 13.05 | |

component efficiency | 22.44% | |

Thermal Properties | Peak solar thermal power (W) | 1180 |

dielectric capacity (L) | 1.2 | |

Media type | Propylene glycol solution / ethylene glycol solution / water | |

Working pressure (MPa) | 0.6 | |

operate mode | Intersticial | |

Interface size and quantity | G1/2 external thread, 2 | |

Heat exchanger structure | Piping | |

Heat exchanger material | red copper | |

other | Back Material | Painted Sheet |

packing quantity | 28 units per pallet, 616 units per 40-foot container | |

Application areas | Low-temperature radiant heating, pool heating, cross-season heat storage, and direct heating integrated with heat pumps |