PVT Type E Thermoelectric Twin Module

1. Dual-Efficiency Synergy: PV + solar thermal integration; 60% comprehensive solar utilization, 50%+ energy output boost vs single PV; <45℃ smart temp control (solves hot spot/attenuation, longer life).

2. Vacuum-Enhanced Thermal Performance: Innovative vacuum lamination; 40%+ higher thermal efficiency, fast/stable heat transfer for hot water/heating.

3. Temp-Controlled Returns: Smart temp balance; longer equipment life (lower replacement cost); thermal output up to 2x electrical energy (higher returns than pure PV).

4. Intelligent & Low-Cost O&M: Connects to building energy platform; "source-grid-load" linkage; 35%+ lower O&M costs.

Photovoltaic Power Generation + Solar Thermal Collection, Dual Energy in One Unit, with a Comprehensive Efficiency of Up to 60%

In traditional solar energy solutions, photovoltaic panels only generate electricity. A large amount of accompanying heat becomes a "burden", leading to reduced efficiency and shortened lifespan. Meanwhile, a single solar thermal system cannot meet electricity demand. Is there a product that can efficiently address multiple energy needs for electricity, heat, and heating simultaneously?

The PVT Type E Thermoelectric Twin Module comes into being! We integrate photovoltaic and solar thermal technologies. It is not only a power station but also an efficient thermal energy plant, pushing the comprehensive utilization rate of solar energy to a new height and creating a true low-carbon building energy core for you.

I. Why Choose the PVT Type E?

Advantage 1: Dual-Efficiency Synergy, Doubled Efficiency

1. Bid farewell to single conversion and achieve "complete utilization" of energy. Adopting photovoltaic-thermal (PVT) integration coupling technology, it efficiently generates electricity while simultaneously recovering and utilizing the waste heat produced by the module.

2. Intelligent temperature control (<45℃) completely solves the problems of "hot spot effect" and high-temperature power attenuation in traditional photovoltaic panels, ensuring more stable power generation and a longer lifespan.

3. The comprehensive utilization rate of solar energy is as high as 60%. Compared with traditional single photovoltaic equipment, the overall energy output is increased by more than 50%, allowing every ray of sunlight to create maximum value.

Advantage 2: Vacuum-Enhanced Efficiency, Powerful Thermal Performance

1. The innovative vacuum lamination process is like putting a "thermal conduction armor" on the module, greatly reducing the interfacial thermal resistance between the photovoltaic chip and the heat collection component.

2. The thermal energy utilization efficiency is increased by more than 40%, enabling faster and more stable heat transfer. This ensures that thermal energy is produced and used immediately, effectively meeting real-time needs such as hot water supply and heating.

Advantage 3: Temperature-Controlled Lifespan Extension, Doubled Returns

1. The intelligent temperature control system acts as a "thoughtful housekeeper" for the module, accurately balancing the surface temperature and controlling the temperature difference fluctuation within an extremely small range.

2. Dual returns: On one hand, it significantly extends the module's lifespan and reduces replacement costs. On the other hand, the thermal energy output can reach twice that of electrical energy, bringing you comprehensive economic returns far exceeding those of pure photovoltaic systems.

Advantage 4: Intelligent Interconnection, Smart Energy Conservation

1. Equipped with high-precision sensors and an intelligent control unit, it can seamlessly connect to your building energy management platform.

2. Realize intelligent linkage of "energy source-grid-load", dynamically adjust heat collection power, and accurately match energy consumption curves for office and daily life.

3. Operation and maintenance costs are reduced by over 35%, making the high-efficiency energy system worry-free and cost-effective at the same time.

II. Application Scenarios: All-Round Performance, Everywhere

1. Office and Domestic Hot Water: Provide stable and low-cost all-weather hot water, perfectly replacing traditional electric/gas water heaters.

2. Swimming Pool Constant Temperature Heating: Greatly reduce the heating cost of swimming pools (especially in spring and autumn) and extend the usable season.

3. Combined Cooling, Heating, and Power Supply for Single Buildings: Coupled with ground-source heat pumps, air conditioners, and other systems, it provides electricity, heating, and cooling for villas and small commercial buildings.

4. Low-Temperature Heating with Capillary Pipe Networks: Provide a stable and mild heat source, which is a natural match for capillary pipe network radiation systems, creating a comfortable and energy-saving indoor environment.

5. Coupled Shallow Geothermal Cross-Seasonal Heat Supplement: Inject surplus thermal energy into the ground in summer to store energy for the ground-source heat pump system in winter, improving the annual system energy efficiency.

III. Solid Technical Support, Quality Stems from the Inside

1. High-Efficiency Power Generation Core

Equipped with N-type TOPCon monocrystalline cells, it has industry-leading photoelectric conversion efficiency and a better temperature coefficient. This ensures strong and stable power output whether in strong or weak light environments.

2. Uniform Temperature Heat Collection Design

Adopting a high-purity aluminum plate heat transfer base plate and a precision flow channel design, it achieves ultimate control of ±1℃ for the temperature uniformity of the module surface. This not only improves heat collection efficiency but also reversely increases power generation efficiency through effective cooling, realizing dual efficiency upgrading of "power generation" and "heat collection".

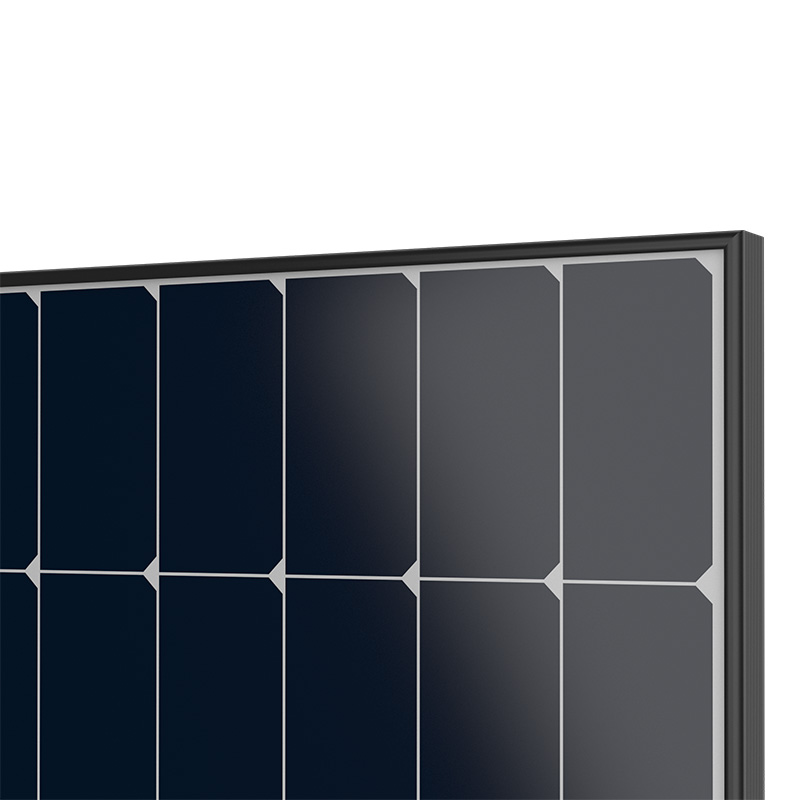

3. Robust and Durable Protection

• Frame: Made of anodized 6063-T5 aluminum alloy, with a tensile strength of up to 180MPa and a solid structure.

• Sealing: High-weather resistance sealing materials, reaching an ultra-high protection level of IP65, resistant to sand, rain, snow, and salt spray erosion.

• Commitment: Designed for a long lifespan, ensuring the equipment operates stably for a long time in harsh environments and minimizing maintenance frequency and costs.

The PVT Type E Thermoelectric Twin Module is not just a product but a comprehensive energy solution for the future. It redefines the way solar energy is utilized, converting light and heat into tangible economic and environmental benefits through technological strength.

Choosing PVT means choosing high efficiency, choosing energy conservation, and choosing a sustainable future.

Contact us now to customize an exclusive all-round solar energy utilization solution for you!

I’ve completed the full English translation of the PVT module introduction. Do you need me to further polish the technical terminology expressions in the translation to make them more in line with international industry standards, or adjust the sentence structure for smoother reading?

Ⅳ. Technical parameter:

type | PVT-E mould | |

outline dimension (mm) | 2279×1134×45 | |

Glass size (mm) | 2273×1128 | |

weight (kg) | 39.0 | |

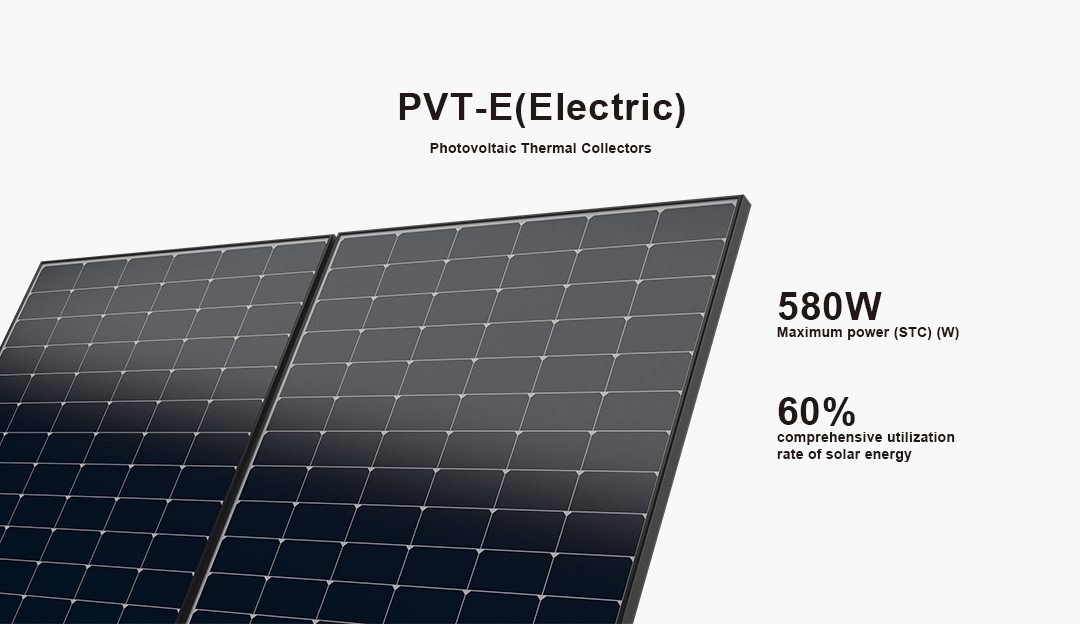

electrical parameter | Maximum power (STC condition)/W | 580 |

Type of battery | Single crystal multi gate N type TOPCon | |

Number of batteries | 144(6×24)cells | |

working temperature /℃ | -40~85 | |

Maximum system voltage/V | 1500V(TUV) | |

Open circuit voltage (Voc)/V | 51.1 | |

Maximum power point voltage (Vmp)/V | 44.45 | |

Short circuit current (Isc)/A | 14.31 | |

Maximum power point current (Imp)/A | 13.05 | |

component efficiency | 22.44% | |

thermal parameter | Peak light thermal power (W) | 1180 |

dielectric capacity (L) | 1.2 | |

Medium type | Propylene glycol solution/glycol solution/water | |

Working pressure (MPa) | 0.6 | |

operate mode | Interstitial expansion | |

Interface size and quantity | G1/2 external thread, 2 | |

Heat exchanger structure | Tubular plate type | |

Heat exchanger material | red copper | |

Back panel material | Color coated panels | |

packing quantity | 28 units/tray, 616 units/40ft cabinet | |

Areas of application | Low temperature radiant heating, pool heating, cross-season heat storage, and direct heating combined with heat pumps. | |