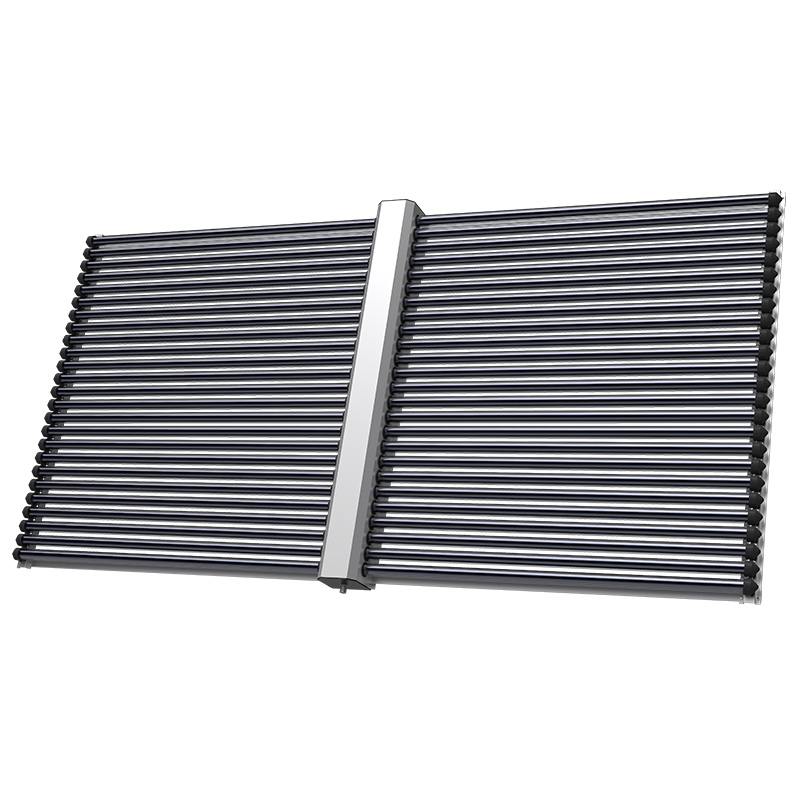

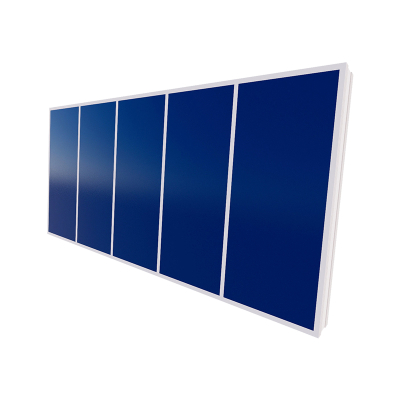

Direct Insertion Manifold Solar Collector

· High-efficiency all-glass vacuum tubes with uniform selective coating

· Strong resistance to thermal shock and long service life

· Weld-free end port design ensures leak-proof performance under high temperatures

· CFC-free German-grade polyurethane insulation for uniform and lasting heat retention

The Direct-Insertion Manifold Solar Collector is a robust and cost-effective solar thermal device specifically engineered for industrial and commercial solar heating systems. Featuring a direct single-loop design, it allows water to be heated and circulated directly between the collector and the storage tank—greatly improving heat exchange efficiency and reducing investment costs.

This system is ideal for

· Industrial process heating and domestic hot water

· Commercial building centralized heating

· Agricultural and livestock heating systems

· Swimming pool temperature control

· Solar-powered district heating networks

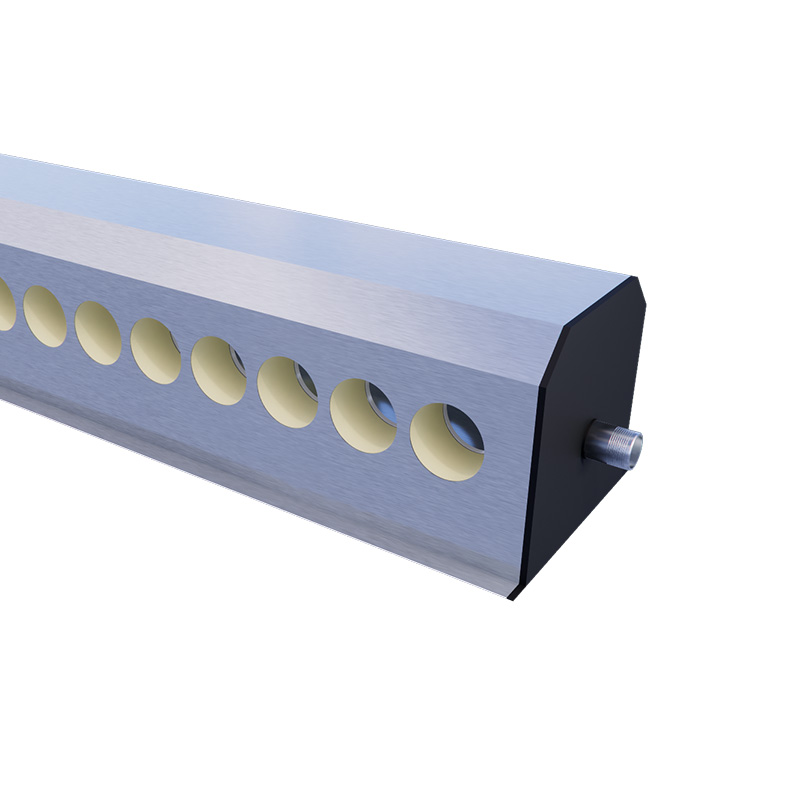

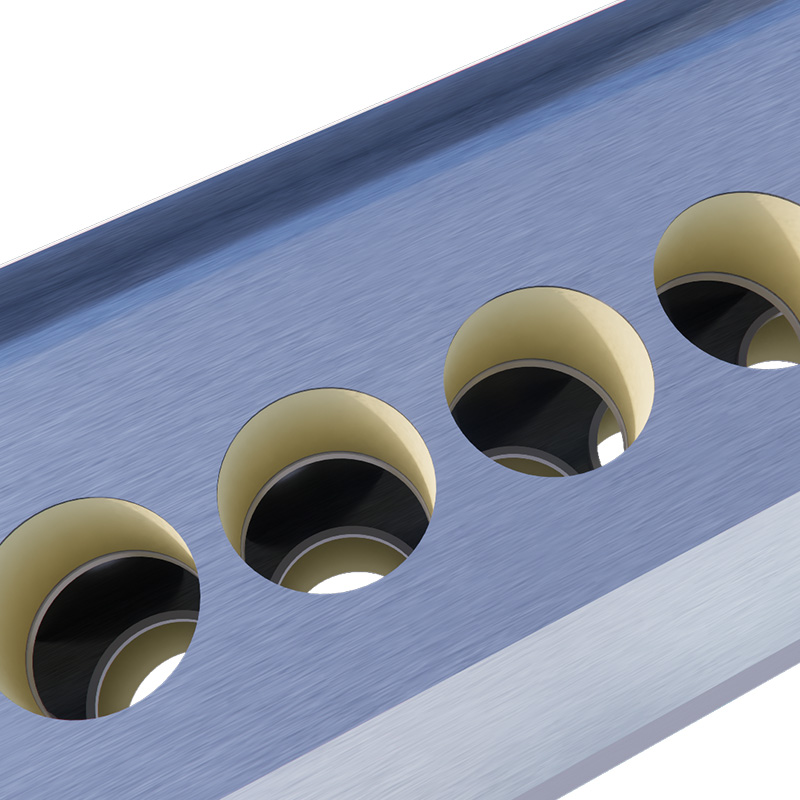

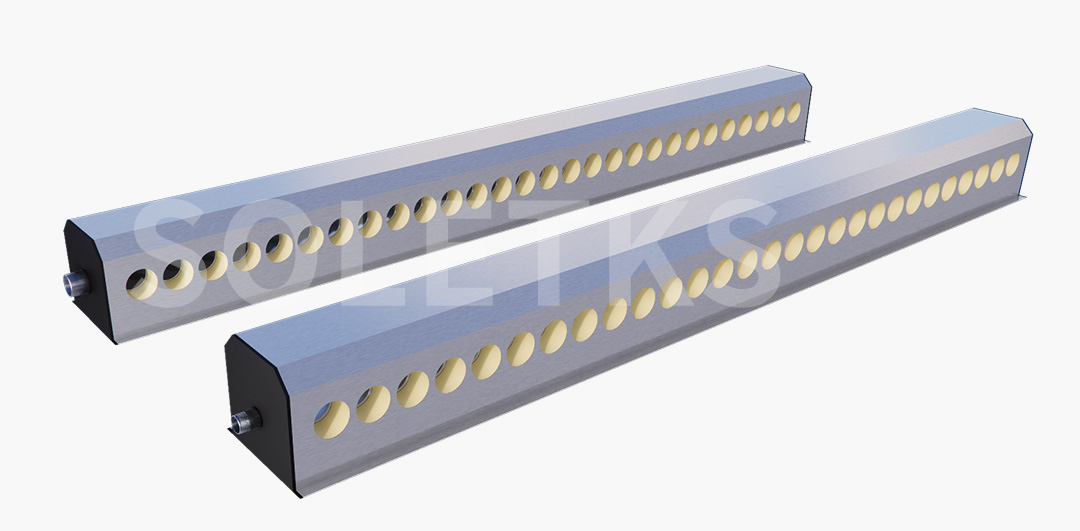

Core Technology: UHS Sealing System

We apply advanced Ultra-High Sealing (UHS) technology to eliminate common leakage issues in conventional systems. The tank features precision double-sided argon arc welding, combined with weld-free press-fit end caps, providing:

· Seamless 360° internal sealing

· Enhanced resistance to corrosion and pressure

· Weld durability up to 15 years

· Maximum pressure resistance up to 1.0 MPa—16x the national standard

Key Product Features

· High-efficiency all-glass vacuum tubes with uniform selective coating

· Strong resistance to thermal shock and long service life

· Weld-free end port design ensures leak-proof performance under high temperatures

· CFC-free German-grade polyurethane insulation for uniform and lasting heat retention

This collector is engineered for performance, reliability, and seamless integration with your industrial or commercial hot water system.

Product Parameter

Type of collector | CTC390 | CTC500 | CTC780 | CTC1490 | |

outline dimension (mm) | 2180×1990×180 | 2580×1990×180 | 3760×2180×180 | 3760×4065×180 | |

Vacuum tube specifications | φ58×1800 | φ58×1800 | φ58×1800 | φ58×1800 | |

Number of vacuum tubes | 25 | 30 | 50 | 100 | |

Contour area (m2) | 3.91 | 5 | 7.81 | 14.91 | |

Lighting area (m2) | 2.47 | 2.96 | 4.93 | 9.86 | |

net weight (kg) | 67 | 81 | 123 | 230 | |

Working pressure (MPa) | ≤0.06MPa | ||||

Interface size | DN25 or DN50 external thread | ||||

Number of interfaces | Two | Three | |||

End cap of inner tank | UHS solder-free structure sealing process | ||||

Total heat loss coefficient | 2.4W/(m2·K) | ||||

Maximum operating temperature (℃) | 100 | 100 | 100 | 100 | |

Peak efficiency | 0.7 | 0.7 | 0.69 | 0.69 | |

rated efficiency ① | 0.59 | 0.59 | 0.57 | 0.57 | |

specified power (kW)② | 400W/m² | 0.4 | 0.5 | 0.8 | 1.5 |

700W/m² | 0.9 | 1.1 | 1.8 | 3.4 | |

1000W/m² | 1.4 | 1.7 | 2.8 | 5.3 | |