Journalists from National, Provincial and Municipal Mainstream Media Visit Soletks: Exploring the Innovation Code of a Green Technology Enterprise

On March 16th, the warm spring sun cast a soft glow over Soletks Group’s Tianqu New Area Industrial Park, where a media delegation focused on "green innovation and sustainable development" began its visit. The delegation brought together journalists from influential media outlets across levels: central media including Guangming Daily (a key national newspaper known for in-depth tech coverage) and Xinhua News Agency (China’s core news wire), provincial platforms such as Dazhong Daily (Shandong’s flagship daily), Economic Herald (a leading business publication), and Dazhong Network · Haibao News (a popular digital news portal), as well as Dezhou Daily (the primary local media for Tianqu New Area). Their mission was clear: to dig into the tech innovation achievements of this new energy enterprise, which holds two prestigious titles—"National-level Specialized, Refined, Peculiar and Innovative Little Giant Enterprise" (a recognition for top-tier small and medium tech firms) and "National High-tech Enterprise"—and learn how it maintains its position as the world’s second-largest producer of flat-plate solar collectors (with annual output exceeding 7.0GWth) while contributing over 10 million yuan in annual taxes, all by adhering to a path of green, low-carbon, and high-quality development.

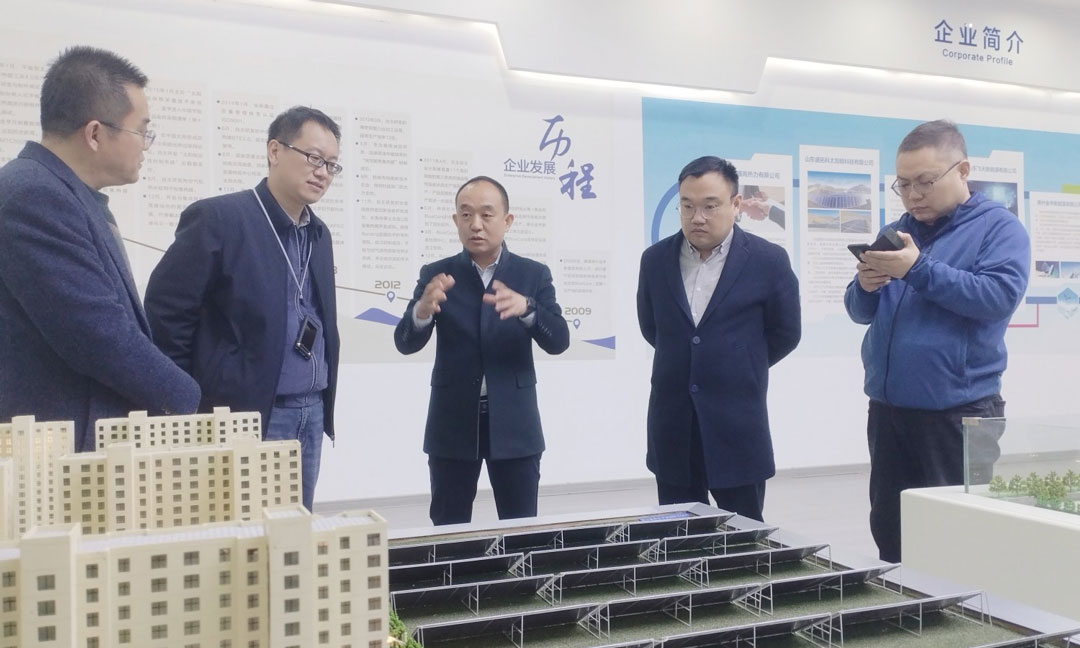

At 10 a.m. sharp, the delegation arrived at Soletks corporate exhibition hall—a 500-square-meter space designed to showcase the company’s 20-year journey in clean thermal energy. Inside, the displays were thoughtfully arranged to tell a story of innovation: on the left, small household solar collectors (ranging from 1㎡ to 2㎡) sat alongside digital screens playing installation videos for rural homes; in the center, a life-sized model of the EFPC high-efficiency integrated flat-plate collector (measuring 4m in length) stood out, with a transparent panel revealing its internal heat-absorbing coating; on the right, a sand table of the Tibet Saga County central heating project (scaled at 1:200) showed the layout of collectors, heat storage tanks, and pipeline networks, with LED lights simulating energy flow. Accompanying the delegation were key Soletks leaders: founder and Chairman Han Rongtao (a senior engineer with over 25 years in solar tech), Chairman Assistant Liu Jia (who oversees corporate communications), and Yan Jijun, General Manager of the International Marketing Center (in charge of global product applications). Throughout the visit, the leaders answered media questions with concrete cases and data, focusing on hot topics like product lifespan, economic advantages, and real-world applications in energy transition.

A journalist from Economic Herald was the first to ask a practical question: "For ordinary users, is the cost of a solar thermal system higher than that of traditional central heating?" Yan Jijun immediately walked the delegation to the Saga County project sand table, pointing to the EFPC collector model: "Saga County is located in the southwest Qinghai-Tibet Plateau, at an altitude of 4,600 meters. Its winter heating season lasts 8 months, with average temperatures dropping to -25℃. We installed 2,000 EFPC collectors here, totaling 8,000㎡ of heat-collecting area. After a full heating season (from October 2023 to May 2024), the actual operation cost was only 15 yuan per square meter—far lower than the 22 yuan/s㎡ charged by the local traditional coal-fired heating network. The reason is high solar utilization: the plateau has over 3,000 hours of annual sunshine, so the system runs mostly on solar energy, with minimal backup energy needed."

A Xinhua News Agency journalist followed up: "Does this 15-yuan cost include the depreciation of the initial investment? Many users worry about high upfront costs." Yan smiled and replied with precise figures: "The total investment for the Saga system (collectors + heat storage + pipelines) was about 20 million yuan. If we calculate based on the traditional heating fee standard (22 yuan/s㎡ for 107,000㎡ of heating area), the annual revenue from heating fees is about 2.35 million yuan. Excluding operation and maintenance costs (around 300,000 yuan/year), the net return is about 2.05 million yuan. This means the investment can be recovered in 5 to 8 years—depending on how well the operator manages energy use. And the system’s design lifespan is 25 years—so after recovery, the remaining 17 to 20 years will bring stable profits. More importantly, it replaces 5,000 tons of coal per year, cutting carbon dioxide emissions by 13,000 tons. It’s a true ‘economic and environmental win-win.’"

When the delegation moved to the "Household Products Area," a Dezhou Daily reporter noticed a compact collector labeled "internal circulation self-draining" and asked: "For rural households that don’t have central heating, do you use large flat-plate tech too?" Han Rongtao picked up the collector (which weighs about 15kg and is 1.2m long) and explained its design philosophy: "Rural areas have unique needs—scattered homes, limited installation space, and no professional maintenance teams. So we developed this product specifically for rural use. Its key innovations are twofold: first, internal circulation—water doesn’t stay in the pipes when not in use, avoiding freezing and cracking in winter; second, high integration—all components (collector, pump, controller) are pre-assembled, so installation takes only 2 hours per household, 40% shorter than traditional systems. This cuts installation costs by 30%. We’ve promoted it in 20 rural villages in Dezhou and Hebei, serving over 1,200 households. Last winter, user feedback was great—indoor temperatures stayed at 18℃ to 22℃, and monthly energy costs were 50% lower than electric heaters."

In the "Cutting-edge Technology Area," a Guangming Daily journalist showed interest in the PVT product (a panel combining solar water heating and power generation) and asked about its market prospects. Yan Jijun replied honestly: "PVT is still a niche product in China. Right now, it’s mainly used in scenarios that need both heat and electricity—like high-end villas, camping resorts, and border outposts (where grid access is limited). But in international markets, especially Europe (Germany, France) and North America (the US, Canada), it’s more popular. These regions have high electricity prices and strong demand for green energy, so our PVT orders there have grown by 30% annually for the past two years. Most of our foreign trade orders (about 80%) are still flat-plate collectors, but PVT is a key growth area for us."

When talking about R&D capabilities, a Dazhong Network journalist asked how Soletks maintains innovation. Yan used a simple "4+3" framework to explain: "First, 4 professional technical departments—each focusing on one area: flat-plate collectors (improving efficiency), thermoelectric twin systems (like T/PV Pro), energy storage technology (batteries + heat storage), and intelligent control (APP-based monitoring). Second, 3 R&D platforms: a national-level flat-plate collector testing center (certified by the Ministry of Industry and Information Technology), which can conduct 20+ tests (like heat loss and durability); a research institute (with 50+ engineers) that works on long-term projects (e.g., next-gen coatings); and a thermal energy college (co-founded with Shandong Jianzhu University) that trains technical talent. We also have strategic partnerships with Tsinghua University and Peking University—their labs do basic research (like new materials), and we turn that into products. For example, the PVD coating technology in our EFPC collectors came from a Tsinghua collaboration."

The "Development History Wall" near the exit caught the delegation’s eye—it had a line graph showing "293-fold growth" in revenue between 2012 and 2015. A journalist from Dazhong Daily expressed surprise: "That growth rate seems incredible. How did you achieve it?" Han Rongtao laughed and explained: "It’s about the base. In 2012, our annual revenue was only 5 million yuan—so even a small increase looked big. By 2015, revenue reached 1.465 billion yuan, which is 293 times more. But as the company scaled up, growth slowed down to a more rational pace. Last year, our 12-year compound annual growth rate (CAGR) was 70%—that’s healthy for a tech enterprise of our size (now with 7 subsidiaries and 6 production bases)."

Before the visit ended, Han Rongtao shared Soletks’s latest strategic move: "Last year, we started our ‘second transformation’—shifting from a ‘clean thermal product manufacturer’ to a ‘total solution provider.’ Before, we just sold collectors; now, we offer one-stop services: site surveys, system design, installation, and 5-year maintenance. Tianqu New Area has supported us a lot in this transformation—they helped with talent recruitment (connecting us to local universities) and policy subsidies (for R&D). Tianqu is a great place for innovative companies—it has a complete industrial chain (suppliers of glass, aluminum) and a supportive government. This gives us more confidence to become a world-class expert in sustainable clean thermal energy."

The 2-hour visit ended with the media delegation expressing praise for Soletks’s innovations. As Han Rongtao said in his closing remarks: "Clean thermal energy is key to China’s ‘dual carbon’ goals (peak carbon by 2030, carbon neutrality by 2060). Our job is to make solar energy cheaper and more accessible—so that more homes, factories, and villages can use green heat. This media visit helps more people understand solar tech, and we’ll keep innovating to contribute to a low-carbon society."