PVT-T Module

I. Maximized Energy Utilization

II. High Efficiency

III. Stable and Durable

Against the backdrop of the in-depth advancement of the "dual carbon" goals, the demand for combined heat and power supply, civil domestic hot water, and heating in low-carbon buildings continues to escalate, imposing higher standards on the comprehensive efficiency, stability, and adaptability of solar energy utilization equipment. The PVT-T thermoelectric twin module, with its core innovative design of integrated photovoltaic-thermal (PV-T) technology, breaks through the single-function limitation of traditional solar energy equipment, becoming a high-efficiency and stable core carrier for comprehensive solar energy utilization. It provides a high-quality solution that balances economy and environmental friendliness for multi-scenario building energy supply.

Working Principle of Photovoltaic-Thermal (PVT) Hybrid Module

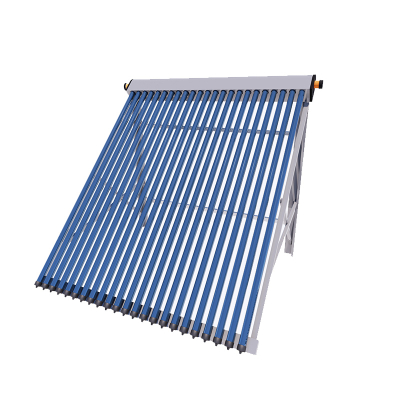

The PVT hybrid module integrates photovoltaic (PV) cells and thermal collectors into a single unit, realizing simultaneous solar energy conversion into electricity and usable heat.

Its working process is divided into three core steps:

Photovoltaic Power GenerationWhen sunlight irradiates the PV cells on the module surface, photons excite electrons in the semiconductor material, creating an electric current that generates electricity directly.

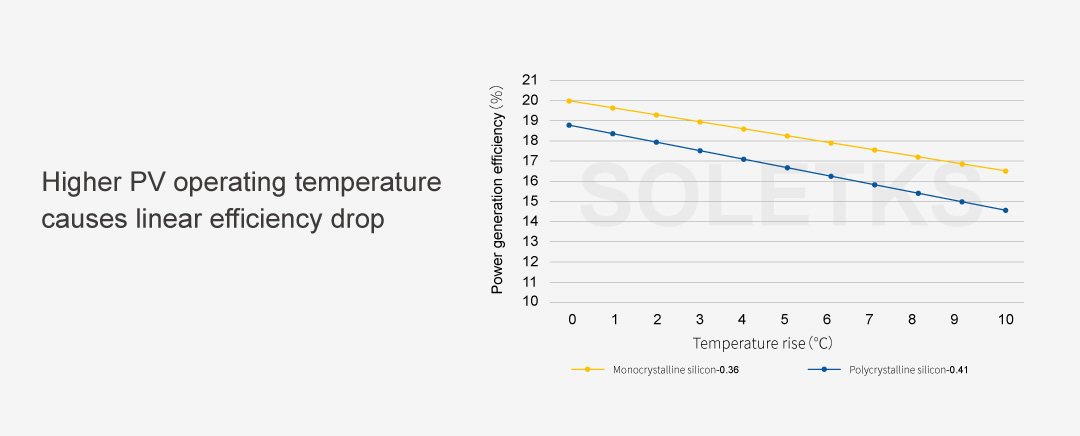

Waste Heat RecoveryOnly a portion of solar energy is converted into electricity by PV cells, with the rest turning into heat. This heat would otherwise raise the cell temperature and reduce power generation efficiency. The integrated thermal collector captures this waste heat immediately via a heat transfer medium (e.g., water or antifreeze liquid) flowing through the collector.

Temperature Regulation & Dual-output OptimizationThe heat transfer medium carries away excess heat, maintaining the PV cells at an optimal operating temperature (typically below 55°C). This not only preserves high photovoltaic conversion efficiency but also delivers the collected heat for applications like space heating or domestic hot water supply.

Core Product Advantages

Combined Heat and Power Supply with Synergistic Dual Effects.

The module innovatively integrates photovoltaic components and high-efficiency heat collection parts, equipped with integrated photovoltaic-thermal coupling technology. While achieving high-efficiency photoelectric conversion, it simultaneously and accurately collects the accompanying heat generated by the photovoltaic cells during operation. This design can stably control the module operating temperature below 55℃, fundamentally avoiding the inhibition of power generation efficiency by high temperatures and ensuring continuous and efficient power output. At the same time, it converts the originally wasted heat into usable energy to meet core needs such as building hot water supply and winter heating, raising the comprehensive solar energy utilization rate to as high as 80% and truly maximizing the value of "one input of solar energy, multiple energy gains."

Vacuum Lamination for Enhanced Efficient Heat Transfer.

Relying on precision vacuum lamination technology, the module achieves seamless and tight bonding between the photovoltaic layer and the heat collection layer, significantly reducing interlayer thermal resistance and improving the heat transfer coefficient. Verified by practical engineering applications, this technology can increase thermal energy utilization efficiency by more than 40%, ensuring that the heat generated during photoelectric conversion is quickly and losslessly transferred to the heat collection system, laying a solid core foundation for the stable supply of subsequent thermal energy.

Three-Dimensional Thermal Insulation for Heat Retention and Consumption Reduction.

Adopting an all-round three-dimensional thermal insulation system design, it constructs a dual heat protection barrier: a high-transmittance cover plate is installed on the front side, and the distance between the module and the cover plate is precisely optimized, effectively reducing front-side heat loss by 70% while ensuring high solar transmittance without affecting photovoltaic power generation efficiency; high-density fiber insulation material is selected for the back side, combined with a long-wave high-reflection film. Even under complex working conditions such as large day-night temperature differences and low-temperature cold, it can effectively block heat loss and ensure stable collection and storage of heat energy.

Intelligent Interconnection for Cost Reduction and Energy Efficiency.

The module is built with high-precision temperature sensors and an intelligent control system, which can seamlessly connect to the building energy management platform, realizing an intelligent operation and maintenance mode with dynamic power regulation of heat and electricity output and real-time monitoring of core parameters. This significantly reduces manual intervention costs, lowering operation and maintenance costs by more than 35%, and markedly improving the economic applicability and long-term operational value of the product.

Diversified Application Scenarios

The PVT-T thermoelectric twin module has a wide range of applicable scenarios and can flexibly meet diverse building energy needs, including centralized hot water supply for office buildings, constant temperature heating of commercial swimming pools, and cross-seasonal heating of heat pump coupled heating systems. It accurately matches the energy consumption characteristics of different building types. Whether for the construction of energy systems in new low-carbon buildings or the energy-saving renovation and upgrading of existing buildings, it can provide efficient and flexible customized energy solutions to help the construction sector achieve carbon emission reduction goals.

Core Technical Support

High-efficiency battery technology to ensure stable output.

The module adopts monocrystalline multi-busbar N-type TOPCon technology cells, which not only have ultra-high photoelectric conversion efficiency but also a low peak power temperature coefficient. Even in complex outdoor environments such as high temperatures and strong ultraviolet radiation, they can maintain stable and reliable power generation performance, providing core guarantee for the continuous and stable supply of electrical energy.

Uniform temperature structure design to improve comprehensive efficiency.

By scientifically optimizing the layout of heat collection parts, using high-purity aluminum plates as heat transfer substrates, and precisely designing the flow channel structure, the temperature uniformity of the module surface is controlled within ±1℃. The balanced temperature distribution effectively avoids the impact of local overheating on power generation efficiency, realizing the simultaneous improvement of power generation efficiency and heat collection efficiency.

High-transmittance cover plate technology for synergistic loss reduction and thermal insulation.

While ensuring high solar transmittance, the front high-transmittance cover plate, combined with optimized spacing design, significantly reduces heat dissipation loss. It forms a synergistic effect with the three-dimensional thermal insulation system to further enhance heat retention and insulation effects and improve the comprehensive energy utilization efficiency.

Robust protection design for extended service life.

It adopts anodized 6063-T5 aluminum alloy frame with a tensile strength of 180MPa, combined with high-weather resistance sealant, making the product's waterproof rating reach IP65. The all-round protection design can effectively resist erosion from harsh environments such as wind and rain, ultraviolet radiation, and temperature difference deformation, significantly extending the service life of the module and reducing long-term operation and maintenance costs.

Product parameters

Type | PVT-T mould | |

Outline dimension (mm) | 2318×1175×80 | |

Weight (kg) | 66 | |

Electrical parameter | Maximum power (STC condition)/W | 500 |

Cell type | Single crystal multi-busbar N-type TOPCon | |

Number of battery cells | 144(6×24)cells | |

Working temperature /℃ | -40~85 | |

Maximum system voltage/V | 1500V(TUV) | |

Open-circuit voltage (Voc)/V | 51.1 | |

Maximum power point voltage (Vmp)/V | 44.45 | |

Short-circuit current (Isc)/A | 14.31 | |

Maximum power point current (Imp)/A | 13.05 | |

Component efficiency | 22.44% | |

Thermal parameter | Peak power of solar thermal (W) | 1380 |

Dielectric capacity (L) | 1.2 | |

Media type | Propylene glycol solution/ethylene glycol solution/water | |

Work pressure (MPa) | 0.6 | |

Operate mode | Intercalation type | |

Interface size and quantity | φ22,4 pieces | |

Structure of heat exchanger | Plate tube type | |

Heat exchanger material | Red copper | |

Backplane material | Color-coated steel plate | |

Applicable fields | Low-temperature radiant heating, pool heating, cross-season heat storage, combined with heat pump direct heating. | |

As an innovative product in the field of comprehensive solar energy utilization, the PVT-T thermoelectric twin module breaks the functional barriers of traditional photovoltaic and solar thermal equipment through the integration of core technologies and structural optimization, realizing efficient synergy of "photovoltaic + solar thermal". It provides strong technical support and equipment guarantee for promoting the low-carbon transformation of building energy systems and helping the achievement of "dual carbon" goals.