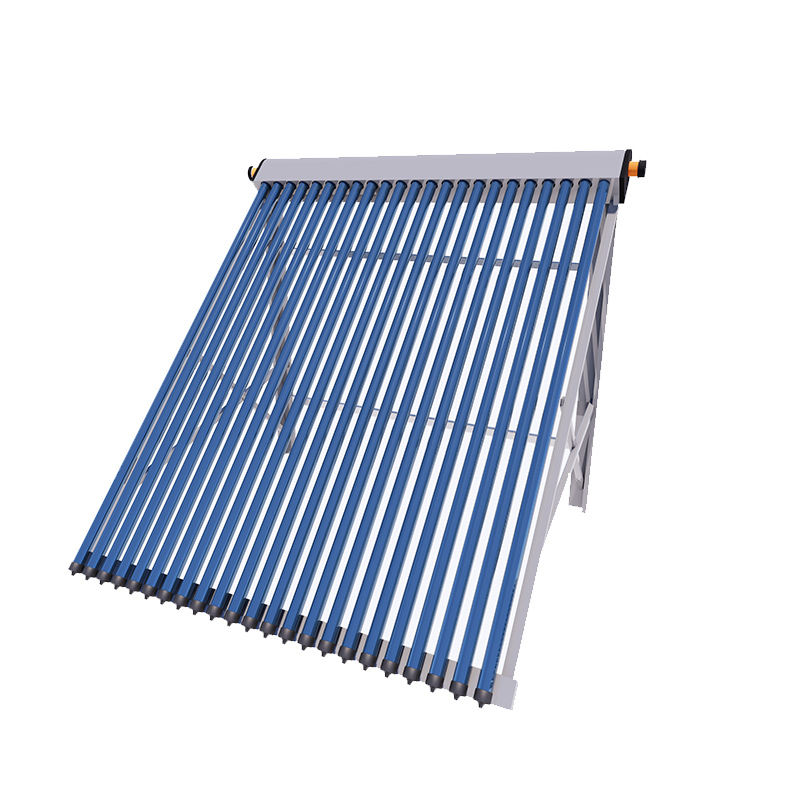

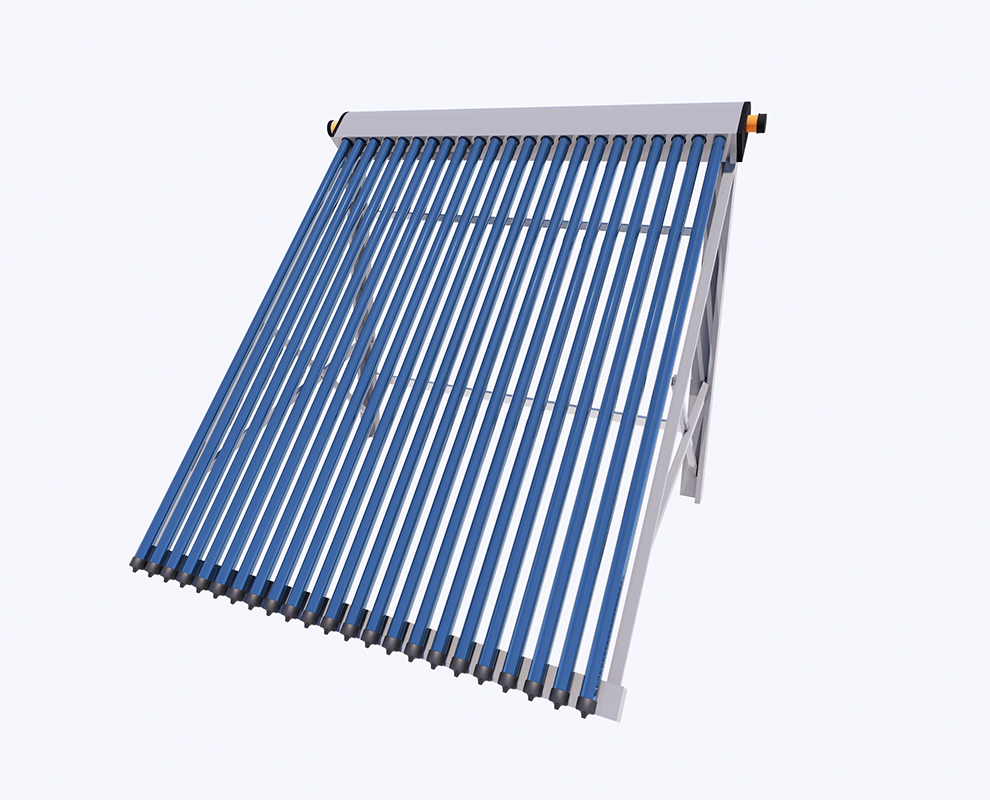

U Tube Solar Collector

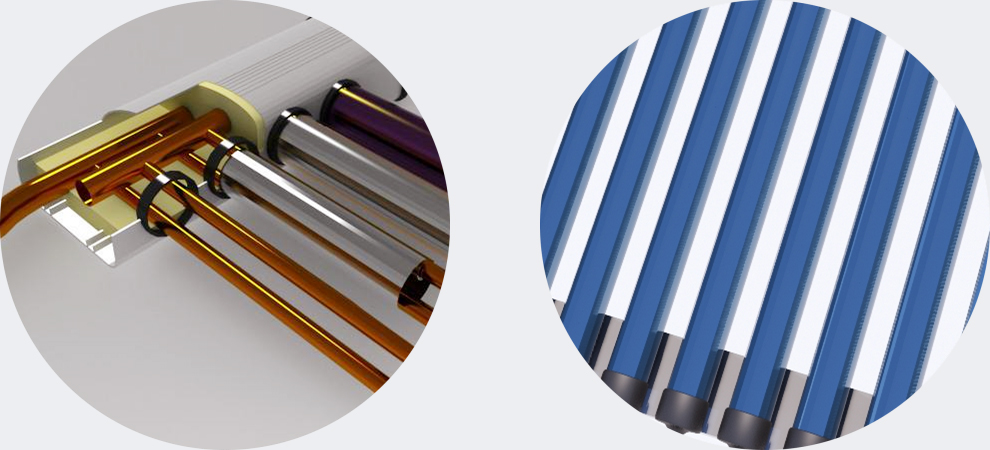

1. Fully closed runner, high toughness welding rod, fast heat transfer, corrosion resistance, long life

2. U-type metal runners for secondary heat transfer, high efficiency of heat collection and fast heat transfer speed.

3. Pressurized operation, no water in the pipe, no pipe blowing in summer, no pipe freezing in winter, no leakage.

4. Customizable product size and structure to achieve architectural integration.

Product Introduction:

The U-tube solar collector is a high-efficiency solar thermal device designed to convert sunlight into usable thermal energy for applications such as water heating, space heating, and industrial thermal processes. This advanced collector system comprises U-shaped copper tubes, high-transparency vacuum tubes, and a finned aluminum collector box, all working together to maximize heat absorption and transfer.

At the heart of the U-tube solar collector is its unique U-tube structure. When solar radiation passes through the vacuum tube, the working fluid inside the U-tube absorbs solar energy and rapidly conducts heat to the manifold. This efficient heat exchange system ensures high thermal output with minimal energy loss, even in colder climates or low-light conditions.

The U-tube solar collector is renowned for its durability, stability, and ease of maintenance, making it ideal for a wide range of residential, commercial, and industrial solar hot water projects. Its modular design allows for flexible installation on rooftops, open grounds, or integration into existing solar water heating systems.

Product Parameters:

Collector Model | U-tube318 | U-tube395 | U-tube472 | |

Overall Dimension(mm) | 1720x1936x156 | 2120x1936x156 | 2520x1936x156 | |

Vacuum tube specification | φ58x1800 | φ58x1800 | φ58x1800 | |

Number of vacuum tubes | 20 | 25 | 30 | |

Contour area(m?) | 3.18 | 3.95 | 4.72 | |

Lighting area(m?) | 2.00 | 2.50 | 3.00 | |

Net weight(kg) | 67 | 86 | 102 | |

Working Pressure(MPa) | 1.0MPa | |||

Interface size | G3/4 male thread | |||

Number of ports | 2 pcs | |||

Total heat loss coefficient | 2.252W/(m2.K) | |||

Maximum working temperature(℃) | 120℃ | |||

Peak efficiency | 0.701 | 0.701 | 0.701 | |

Rated Efficiency | 0.59 | 0.59 | 0.59 | |

Rated power (kW)2 | 400W/m2 | 0.34 | 0.42 | 0.50 |

700W/m2 | 0.76 | 0.95 | 1.62 | |

1000W/m2 | 1 18 | 1.47 | 1.77 | |

Work material capacity (L) | 3.84 | 4.8 | 5.75 | |

Application Scenario:

Applicable to towns, industrial parks, hotels, schools, hospitals, recreational facilities and other types of centralized heating, hot water needs

Product Advantages:

Fin: 3003 antirust aluminum material

Advantage:corrosion resistance, no rust, fast heat transfer

Runner: Copper material

Advantage: corrosion resistance, fast heat transfer

Welding: silver copper welding rod

Advantage: strong toughness, strength, corrosion resistance

Medium: according to the different ambient temperatures to choose a different heat transfer medium

Company Strength:

The company collaborates with seven top research institutions — including the Chinese Academy of Sciences, Tsinghua University, and the Shandong Academy of Sciences — to drive the transition of solar energy applications from conventional "hot water" systems to advanced "flat-plate clean thermal energy." We have established seven R&D departments, one research institute, one academician workstation, one laboratory, and one thermal energy institute. With an annual output of 7.0 GWth of flat-plate clean thermal energy equipment, the company ranks second globally in flat-plate collector production. We possess core technology and a dedicated production line for solar spectrum selective absorption coatings, holding the top market share in core materials across the industry.

The company has been recognized as a National High-Tech Enterprise, a “Specialized and New” Enterprise in Shandong Province, a Shandong Gazelle Enterprise, and has received distinctions such as the Shandong Academician Workstation and Shandong Enterprise Technology Center.

International Projects:

Domestic Projects: