Industrial Drying System: An Efficient and Eco-Friendly Solution for Multiple Fields

In industrial production, drying is an indispensable process. From wood processing and paper manufacturing to chemical production and sludge treatment, various industries have strict drying requirements. With unique advantages, the industrial drying system plays a key role in meeting these needs and is becoming a driving force for green, efficient industrial development.

I. Wide Applicability: A Versatile Drying Expert

The industrial drying system suits diverse industries, including municipal administration, printing and dyeing, papermaking, chemical engineering, and leather processing. In municipal work, sludge treatment is challenging—urbanization boosts sludge output, and traditional methods are inefficient and risk secondary pollution. The drying system solves this by reducing sludge volume and weight, simplifying subsequent disposal.

In printing and dyeing, fabrics need drying post-dyeing to ensure color stability and quality. The system adjusts temperature and time based on fabric traits, preventing deformation or fading from over-drying. For papermaking, it quickly removes excess moisture from new paper, boosting production efficiency and quality. It also meets needs in chemical and leather sectors, from drying chemicals to tanning leather.

II. High-Efficiency Volume Reduction: Cutting Costs

With over 80% volume reduction, the system saves enterprises significant transportation costs. Take sludge: undried sludge has high moisture and large volume, demanding much transport space. After drying, its moisture, volume, and weight drop sharply, lowering transport expenses—critical for large-scale enterprises to save annually. It also reduces storage space for materials like sludge, improving site utilization.

III. Precise Control: Intelligent Technology in Action

Adopting intelligent temperature control, the system ensures precise, scientific regulation. Equipped with advanced sensors and a control system, it monitors drying box temperatures in real time and adjusts automatically per preset parameters. Different materials need different temperatures: for heat-sensitive ones, it keeps temperatures low to avoid damage; for high-temperature needs, it rapidly reaches and maintains the target. This precision improves drying quality and reduces energy waste.

IV. Energy Efficiency: Embracing Green Energy

Using sunlight as the source and air as the medium, the system supplies heat on demand for high energy efficiency. Solar energy—clean and renewable—is fully utilized via heat collectors that convert it to thermal energy for drying. This reduces reliance on fossil fuels, cutting energy use and carbon emissions. The system also adjusts heat supply based on actual needs to avoid waste. In sunny areas, it can rely almost entirely on solar energy.

V. Safety and Environmental Protection: Guarding the Environment

Solar-to-thermal drying makes the system smoke-free, dust-free, and safe. Unlike coal-fired or oil-fired drying, it produces no harmful gases or dust, complying with strict environmental rules and gaining enterprise favor. It also avoids dangerous links like open flames or high pressure, lowering production risks and ensuring worker safety and stable operations.

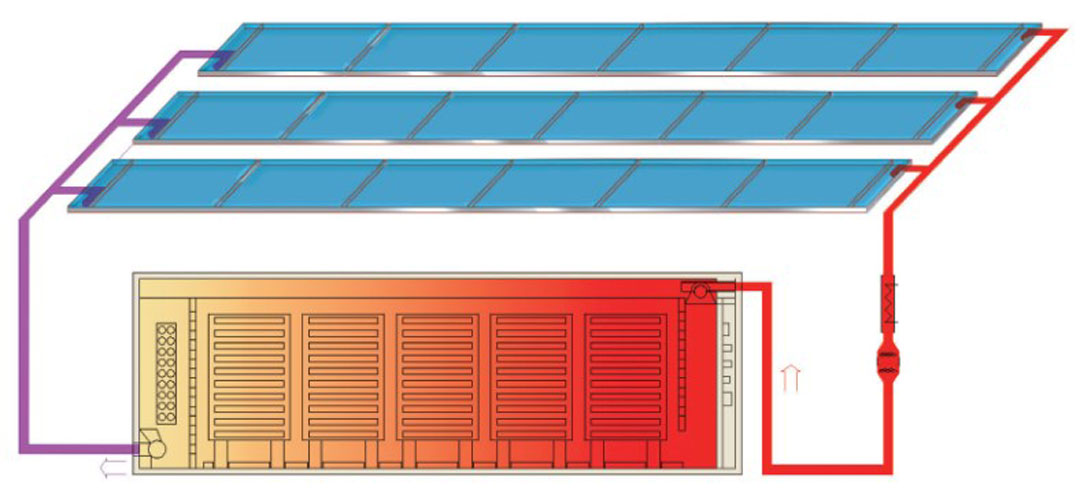

VI. System Operation Principle

The system’s diagram shows key components: heat collectors, a drying box, circulation pipelines, and an intelligent control system. Heat collectors absorb and convert solar energy to heat, which is sent to the drying box via pipelines. Inside, heat evaporates material moisture for drying. The control system monitors and adjusts the entire process for stable, efficient operation.

VII. Key Operation Parameters

Take a 10-ton daily sludge treatment system: it uses DVC500 heat collectors (560㎡ area for full solar absorption), 310kW heating power, and 60-80℃ controllable box temperature—meeting diverse material needs. It saves 4.3×10^5 kWh yearly and cuts CO₂ by 181 tons, with a 3-year payback period for high ROI. Auxiliary heat sources (air energy, natural gas, electric boilers) can be chosen based on local resources, enhancing flexibility.

With wide applicability, high-efficiency volume reduction, precise control, energy efficiency, safety, and reasonable parameters, the industrial drying system is essential for industrial production. As technology advances, it will be applied in more industries to drive greener, more efficient industrial growth.