Aquaculture Constant Temperature System: An Intelligent Temperature Control Solution Empowering Modern Agriculture

As a professional temperature control equipment developed for aquaculture scenarios such as livestock, poultry, and aquatic products, the Aquaculture Constant Temperature System has become a key device to solve the problem of traditional aquaculture "relying on the weather" and improve aquaculture efficiency and quality, thanks to its core advantages of customization, intelligence, low cost, and high reliability. It is widely applicable to livestock and poultry houses for pigs, broilers, layers, etc., as well as aquatic breeding ponds for fish, shrimp, crabs, etc., creating a stable and suitable growth environment for various aquaculture organisms.

In terms of "customization", the system relies on a mature temperature control technology system and can provide diversified solutions to perfectly adapt to different aquaculture scenarios and facility conditions. For newly-built standardized aquaculture parks, it can design exclusive temperature control solutions according to the indoor area, aquaculture species, and local climate characteristics to achieve accurate matching between equipment and buildings. For the renovation of old aquaculture houses, there is no need for large-scale demolition and reconstruction of the original structure; instead, the system can be built through modular components and flexible installation methods, minimizing the transformation cost and the impact on aquaculture production. For example, for broiler houses in cold northern regions, the system can enhance the heat preservation and auxiliary heating modules; for aquatic breeding ponds in hot and humid southern regions, it focuses on heat dissipation and ventilation design. It truly achieves "one scenario, one solution" to meet the personalized needs of different users.

"Intelligence" is the core support for the system to improve aquaculture management efficiency. The system is equipped with an automatic circulation control system, which collects real-time temperature data in the house or pond through temperature sensors distributed in the aquaculture space and transmits it to the control center. When the temperature deviates from the preset range, the system can automatically start heating, cooling, or ventilation equipment to achieve 24-hour uninterrupted constant temperature control, with a temperature control accuracy of ±0.5℃. This completely eliminates the predicament of traditional aquaculture relying on manual on-duty and low temperature control accuracy. For example, in the piglet nursery house, the system can stably maintain a suitable temperature of 28-32℃ to avoid piglet stress caused by temperature fluctuations; in aquatic breeding, it can accurately control the water temperature within the optimal growth range of fish, significantly improving the survival rate and growth rate.

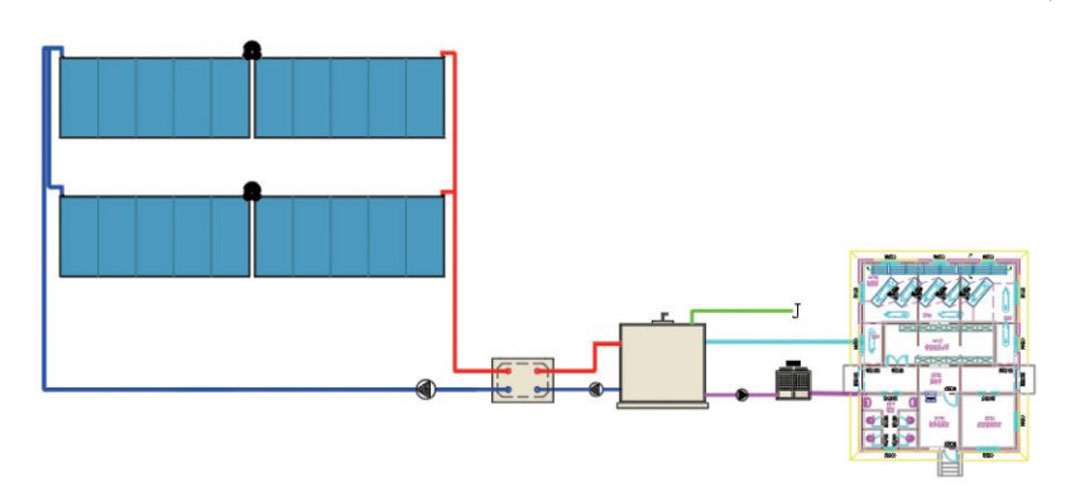

The "low-cost" operation advantage reduces the operating burden for aquaculture enterprises. The system innovatively adopts a "solar energy +" multi-heat source combination mode, giving priority to using solar heat collection devices to obtain free solar heat and provide basic energy for temperature control. When sunlight is insufficient, it automatically switches to air energy, geothermal energy, or a small amount of auxiliary electric energy, forming an efficient energy structure of "solar energy as the main source + clean energy as the backup". Compared with traditional temperature control methods such as electric heating and coal-fired boilers, the operating cost is reduced by more than 60%. Taking a broiler house with a scale of 10,000 birds as an example, after adopting this system, the temperature control energy cost in a single batch of aquaculture cycles can be saved by tens of thousands of yuan, and long-term use can bring significant economic benefits to enterprises.

In addition, the system also has a "high-level" reliability. Its core control unit adopts an industrial-grade PLC programming computer controller, which has the characteristics of strong anti-interference ability, stable operation, and long service life. It can work stably under complex conditions such as high humidity and dust commonly found in aquaculture environments, avoiding temperature control failure caused by controller malfunctions. At the same time, the controller supports remote monitoring and data query functions. Aquaculture staff can view real-time temperature data and equipment operation status through mobile phones or computers, and even adjust parameters remotely, further improving management convenience and system reliability, and providing solid temperature control support for modern aquaculture.