Centralized Heating System: An Efficient and Energy-Saving Heating Solution

In cold seasons, heating systems are critical for maintaining comfortable living and production environments. The centralized heating system stands out as an ideal choice for diverse scenarios due to its multiple advantages. Below is a detailed breakdown of the system, covering its characteristics, operation principle diagram, and key parameters.

I. System Characteristics

(1) Professional Design: The Basis for Efficient Operation

Designed by experienced experts from design institutes, the centralized heating system benefits from their deep understanding of heating technical standards and thermal engineering principles. During design, factors like building structure, heating needs, and local climate are fully considered. Every step—from overall system layout to component selection and matching—undergoes strict calculation and analysis. This professional approach ensures optimal heat generation, transmission, and distribution, laying a solid foundation for efficient, stable system operation.

(2) High Thermal Efficiency: Boosting Energy Utilization

This system’s heat collection efficiency is 30% higher than that of ordinary flat-panel systems. The advantage comes from advanced heat collection technology and high-quality materials. As the core component for absorbing solar or other heat sources, the specially designed heat collector captures more heat under the same conditions and transfers it to the heat transfer medium. Higher efficiency means less energy consumption for the same heating demand, aligning with energy-saving and environmental goals.

(3) Stability & Reliability: Ensuring Uninterrupted Heating

The system features high design pressure and fewer connection points. High pressure tolerance allows it to withstand extreme conditions (e.g., thermal expansion from cold weather) without leaks or damage. Fewer connections—typically weak points prone to leakage or loosening—greatly reduce failure risks. This ensures stable operation and continuous heating supply for users.

(4) Short Construction Period: Speeding Up Project Delivery

Heat collector installation time is cut by 80%, thanks to standardized, modular component design. Key parts like heat collectors are mostly produced and tested in factories; on-site work only involves simple assembly and connection. This modular method reduces complex on-site procedures, letting workers finish installation faster. A shorter construction period not only gets heating online sooner for users but also lowers costs and reduces resource waste from prolonged work.

(5) Time, Cost, and Worry Savings: Comprehensive Benefits

A shorter construction period reduces auxiliary material needs, directly lowering procurement costs. The system’s high stability also minimizes post-operation faults and maintenance expenses, cutting user costs. Additionally, less frequent maintenance means users avoid troubleshooting hassles and can focus on other priorities.

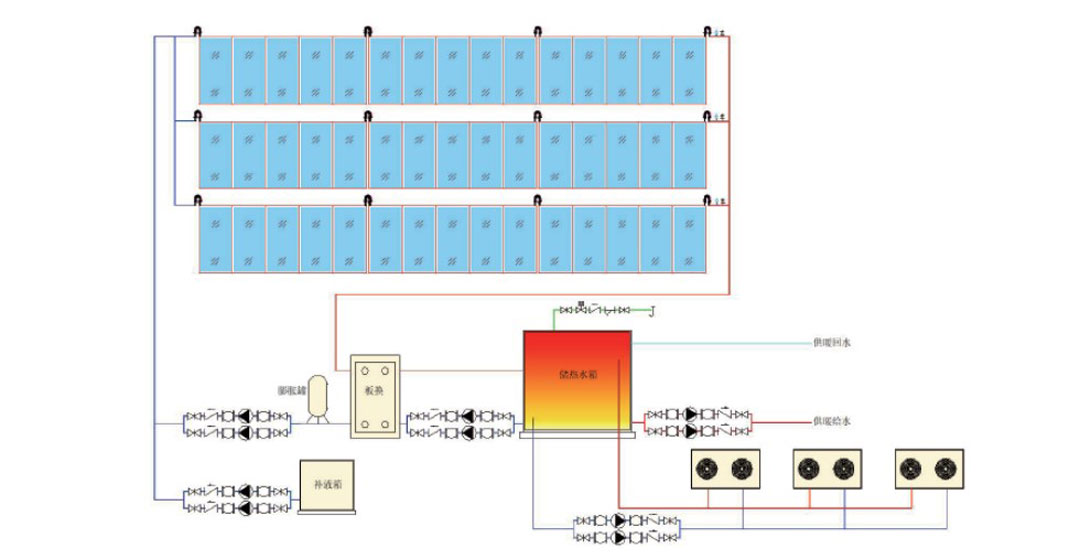

II. System Operation Principle Diagram

The operation principle diagram outlines the system’s workflow and component connections. Multiple heat collectors—core heat-absorbing parts—are arranged at the top, linked via pipelines to lower equipment like the hot water storage tank. A circulating pump drives the heat transfer medium (usually water or heat-conducting liquid) to move heat from collectors to the storage tank. An expansion tank balances pressure fluctuations to prevent system damage, while a make-up pump replenishes the medium when levels drop, ensuring normal operation. The storage tank then distributes hot water to terminal devices (e.g., fan coils), which release heat indoors to achieve heating. Coordinated component work enables heat absorption, storage, and distribution for stable user service.

III. System Operation Parameters

(1) Heating Area & Total Building Heat Load

• 60,000 ㎡ area: 50 W/㎡ heat load → total heat load = 60,000 × 50 = 3,000,000 kW

• 80,000 ㎡ area: total heat load = 4,000,000 kW

• 100,000 ㎡ area: total heat load = 5,000,000 kW

Larger areas require more heat, demanding stronger system heating capacity.

(2) Solar Guarantee Rate & Heat Collector Details

The solar guarantee rate is 60%—60% of heat comes from solar energy, with the rest from auxiliary sources. The matched heat collector model is EFPC115 (11.43 ㎡ per unit). Required quantities vary by area:

• 60,000 ㎡: 1,234 units

• 80,000 ㎡: 1,645 units

• 100,000 ㎡: 2,057 units

More collectors ensure sufficient solar absorption for larger heating areas.

(3) Auxiliary Energy Configuration

Auxiliary energy uses 50P ultra-low temperature air-source heat pumps:

• 60,000 ㎡: 16 units

• 80,000 ㎡: 21 units

• 100,000 ㎡: 26 units

These pumps supplement heat during solar shortages (e.g., rainy days), maintaining stable heating performance.

(4) Annual Energy Savings

Energy savings grow with heating area:

• 60,000 ㎡: 1.6 × 10^7 kW·h/year

• 80,000 ㎡: 2.1 × 10^7 kW·h/year

• 100,000 ㎡: 2.7 × 10^7 kW·h/year

This data highlights the system’s energy-saving value, reducing user costs and carbon emissions.

In summary, the centralized heating system—with professional design, high efficiency, stability, short construction time, and cost savings—plus rational parameter configuration, is an efficient, reliable solution. It meets diverse area needs and creates warm, comfortable environments for users.