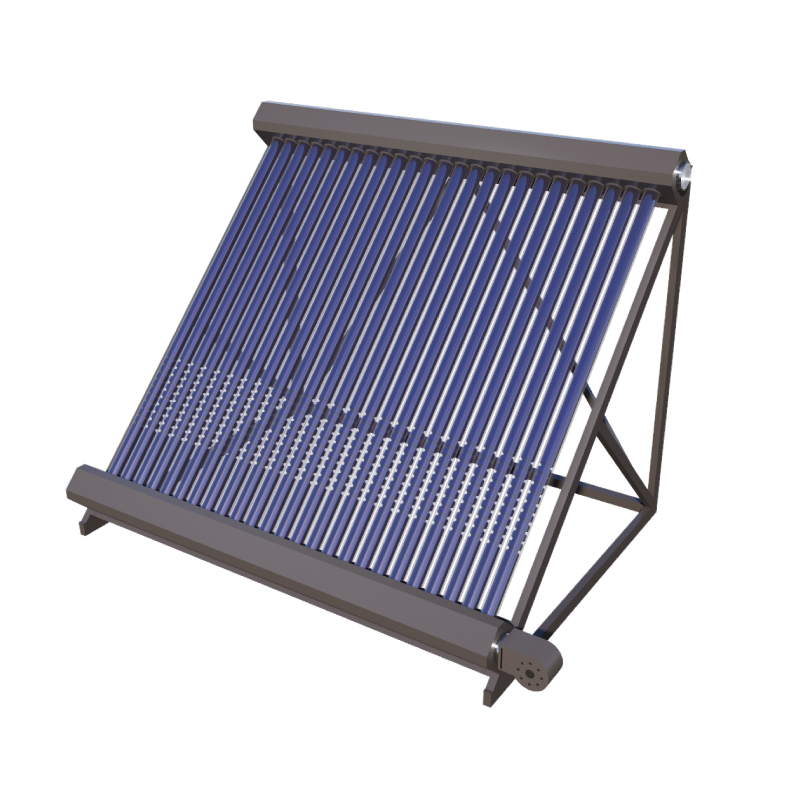

DVC Double Pass Vacuum Tube Air Collector

1. Innovative structure: Air heat transfer, safe and no hidden danger

2. Top Process: High Absorption, Low Consumption, Full Thermal Efficiency

3. Extreme Fit: Durable and Safe, with a Lifespan of Over 50 Years

4. Multi-energy coupling: Heat pump adaptation for higher efficiency in severe cold

Ⅰ. Product Overview: New Choice of Solar Heating

The DVC air collector utilizes air as the heat transfer medium, harnessing solar energy to meet indoor heating and drying needs, completely eliminating the reliance on liquid working fluids in traditional solar systems.

Through three core designs—DC double-pass glass heat pipe, interference coating technology, and inner tube expansion joint—it fundamentally resolves traditional solar energy's pain points like' frozen-cracked burst tubes 'and' cold-hot broken tubes,' delivering cost-effective and reliable heating solutions for schools, office buildings, workshops, drying rooms, and similar scenarios.

Ⅱ. Product Features: DVC500 Dual-Path Vacuum Tube Air Collector

1. Innovative structure: Air heat transfer, safe and no hidden danger

• Medium Innovation: Using air instead of liquid as the working medium, the system directly heats air and circulates it for heat transfer. It can provide direct heating or indirect heating through heat exchangers, compatible with various systems.

• Key components: The expansion joint features a fully glass double-pass vacuum collector tube with a head-to-tail interconnection design, which reduces ventilation resistance and ensures sufficient airflow. This design effectively prevents equipment damage caused by liquid freezing and expansion.

2. Top Process: High Absorption, Low Consumption, Full Thermal Efficiency

• Magnetron sputtering coating: the solar absorption rate is 93% (±2% @AM1.5), the thermal emissivity is only 6% (±2% @80℃), the energy is captured to the maximum and the heat is reduced.

• Exceptionally high conversion efficiency: The system achieves over 80% solar thermal conversion efficiency, maintaining stable heat collection even in cloudy or high-altitude areas, with rapid temperature rise to meet demands.

3. Extreme Fit: Durable and Safe, with a Lifespan of Over 50 Years

• Wide temperature range: maximum operating temperature 280℃+, suitable for high temperature drying; air medium is not affected by cold, stable operation in high altitude and strong radiation environment.

• Structural protection: The inner pipe expansion joint cushions thermal stresses to prevent vacuum tube rupture. With no liquid working medium, it eliminates leakage and corrosion risks, ensuring maintenance-free operation throughout.

4. Multi-energy coupling: Heat pump adaptation for higher efficiency in severe cold

It can be integrated with an air-source heat pump to form a coupled system. During daytime, the heat pump preheats the space, which improves COP (Coefficient of Performance) under low-temperature conditions and reduces energy consumption. This achieves stable year-round heating, effectively addressing the heating challenges in severely cold regions.

Ⅲ. Four Core Advantages: Building Competitive Barriers

1. Dual-through DC Vacuum Tube: Low Resistance and High Air Volume

• The head-tail interconnection design reduces ventilation resistance by over 30% compared to conventional products, delivering greater airflow at the same fan power.

• The temperature distribution is uniform, preventing localized overheating or underheating, enhancing heating comfort, and reducing dust accumulation in the pipes.

2. Ultra-high heat collection efficiency: energy saving and cost reduction

• With dual enhancement from interference coating and magnetron sputtering, the solar thermal conversion efficiency exceeds 80% (compared to the conventional 60%-70%).

• Zero electricity and gas bills, long-term usage saves substantial energy costs, balancing economy and environmental protection.

3. Full-scenario adaptability: Safe and durable

• With high-temperature resistance, cold resistance, and high-altitude adaptability, it operates stably at 280℃ and-30℃ respectively.

• Expansion joint with anti-breakage tube, liquid-free working medium for leak-proof, ultra-long service life, maintenance-free and worry-free.

4. Environmental protection technology: green and high quality

• The product utilizes German constant-temperature integrated foaming technology, with high-pressure filling of environmentally friendly non-fluorinated polyurethane.

• The foaming layer is uniform and dense, which improves the insulation, structural strength and weather resistance, and no harmful substances are released.

Ⅳ. Applicable scenarios: Covering diverse needs

Scene type | adaptation needs | Core advantages are evident. |

building heating | School classrooms, office buildings, workshops, and station buildings are heated | Efficient heat collection, rapid heating, and uniform temperature distribution |

professional drying | Drying of agricultural products, medicinal materials, and industrial goods | Maximum temperature of 280℃, no pollutant emissions |

Heating in cold regions | Centralized heating in residential areas and heating for commercial complexes | Coupled with heat pump to improve COP value and stabilize heating |

Ⅴ. Why choose DVC air collectors?

• Comprehensive solution for all pain points: Eliminate freeze cracks, pipe fractures, and leaks, ensuring reliable performance in extreme environments.

• Outperforming industry peers: Achieving over 80% solar thermal conversion efficiency, delivering significant energy savings and cost reductions.

• Guaranteed lifespan: 50+ years of service life with maintenance-free operation, reducing future costs.

• Full-scenario compatibility: Suitable for both heating and drying, and maintains stable operation even in severely cold regions.

The DVC air collector revolutionizes solar heating through cutting-edge technology, offering an optimal green energy solution to advance the 'dual carbon' goals.

Collector type | DVC500 | DVC850 | |

outline dimension (mm) | 2430×2100×200 | 4030×2100×200 | |

Specification of double conduit | Φ58×1800 | Φ58×1800 | |

Number of dual pipes | 30 | 50 | |

Total area (m²) | 5.1 | 8.5 | |

Lighting area (m²) | 3.8 | 6.3 | |

net weight (kg) | 75 | 125 | |

Rated air volume (m³/h) | 150 | 250 | |

Interface size | |||

Number of interfaces | |||

Total heat loss coefficient | |||

maximum working temperature | 0.76 | 0.76 | |

Peak efficiency | 0.66 | 0.66 | |

rated efficiency ① | 2.5 | 4.2 | |

specified | 400W/m² | 0.76 | 1.62 |

power (kW)② | 700W/m² | 1.25 | 2.69 |

1000W/m² | 2.5 | 4.2 | |

VI. Core Strengths of SOLETKS Group

1. Technology R&D: Leading Global Innovation

• Patent portfolio: 117 core patents and industry-specific solutions.

• Breakthrough in core technology: one of the few global companies capable of mastering both blue and black film production technologies simultaneously.

2. Manufacturing: Intelligent Manufacturing Capability of Industry 4.0

• Production capacity: With six manufacturing bases, one collector can be produced every 55 seconds.

• Quality Control Standards: Implementing end-to-end quality control from core materials to finished products, with products certified to EU CE standards.

3. Industrial chain layout: full-scenario service capability

• End-to-end control: We independently manage all critical components including core materials, production equipment, and system design. As the industry leader in core material market share, we serve over 30 application scenarios across 17 categories.

• System Solutions: We provide end-to-end services covering project survey, design, construction, and commissioning.

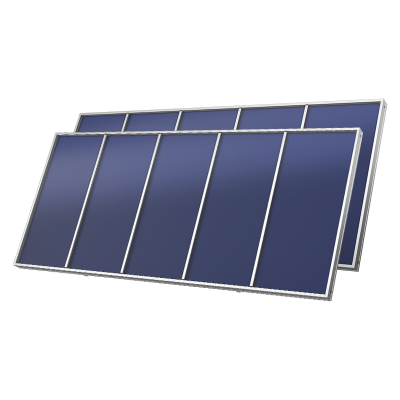

4. Brand Reputation: A Globally Recognized Industry Benchmark

• Market Position: As the world's second-largest producer of flat plate collectors, we export to over 40 countries, with applications spanning construction, industrial, and agricultural sectors.

• Green contributions: A total of 16.726 million tons of CO₂ emissions have been reduced, equivalent to planting 700 million trees, and the company has received multiple honors including the national 'Pacesetter' award for solar thermal products.

Contact us now to learn more or request a quote.

Mail: info@soletks.com

Official website: www.soletks.com

Headquarters: China · SOLETKS Group