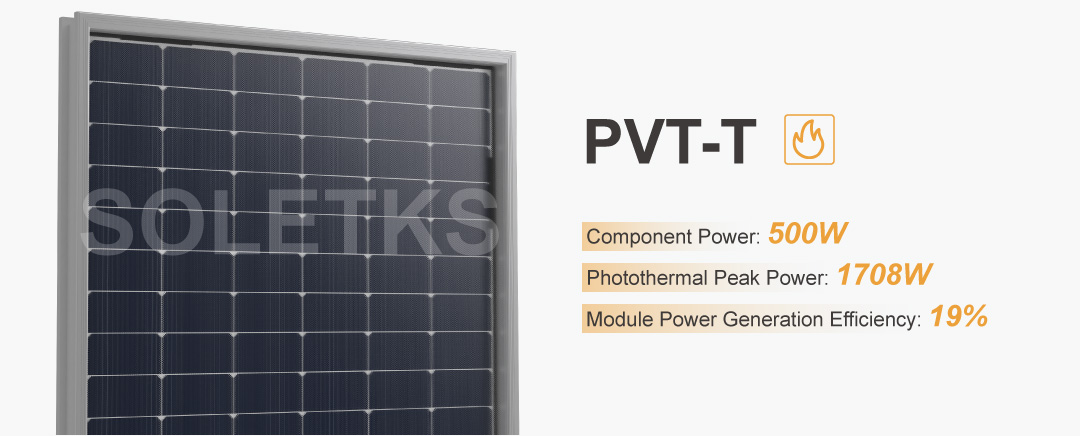

Photovoltaic-Thermal (PVT-T) Hybrid Module

1. Combined Heat and Power, Dual-effect Synergy: Integrated photovoltaic-thermal design, 80% solar energy utilization rate, higher energy output density.

2. Vacuum Bonding for High-efficiency Heat Transfer: Reduced interfacial thermal resistance, over 40% improvement in heat transfer efficiency, stable thermal output guaranteed.

3. 3D Thermal Insulation for Low Heat Loss: 70% reduction in front-side heat loss, efficient heat collection and retention even in extreme environments.

4. Smart Connectivity for Cost Efficiency: Real-time monitoring and regulation, over 35% cut in O&M costs, better energy cost-effectiveness.

Ⅰ. Product Overview

The PVT-T thermoelectric twin module is a high-performance core device integrating photovoltaic power generation and solar thermal collection. Utilizing advanced photovoltaic-thermal integration technology, this product breaks through the traditional single-energy mode of solar modules by simultaneously generating electricity and thermal energy. Specifically designed for diverse applications including low-carbon building cogeneration, residential hot water supply, commercial hot water provision, swimming pool heating, heat pump coupled heating, and cross-seasonal heating, it delivers efficient, stable, and intelligent integrated energy solutions for users.

II. Core Advantages

1. Combined Heat and Power (CHP), Dual Effect Synergy

The module employs integrated photovoltaic-thermal thermoelectric coupling technology, innovatively combining high-efficiency solar cells with heat collection components. During power generation, it simultaneously captures the heat generated by the cells, maintaining the module's operating temperature below 55°C. This achieves both high electrical output and continuous usable thermal energy production. The design significantly boosts solar energy utilization efficiency to 80%, truly realizing the "dual-purpose solar energy" concept and substantially enhancing energy output density.

2. Vacuum bonding for efficient heat transfer

The advanced vacuum bonding process tightly integrates photovoltaic modules with heat collection components, significantly reducing interfacial thermal resistance and enhancing heat transfer efficiency. This technology improves thermal energy transfer efficiency by over 40%, ensuring rapid and efficient heat transfer from solar cells to the heat collection medium, thereby guaranteeing high-efficiency and stable thermal output.

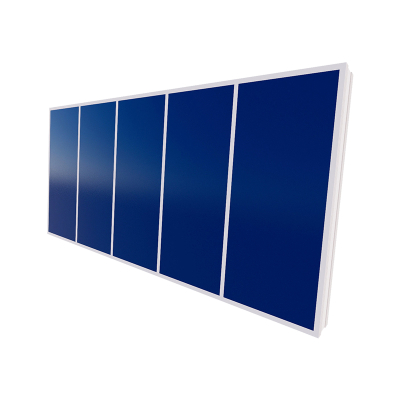

3. 3D Thermal Insulation System for Efficient Heat Retention

The module features an innovative three-dimensional insulation design to minimize heat loss. The front panel incorporates a high-transparency cover plate, with precisely controlled spacing between the cover and module components effectively suppressing convection and radiation heat dissipation, reducing front-end thermal loss by 70%. The back panel utilizes high-density fiber insulation material combined with a long-wave high-reflection coating to form an efficient thermal barrier. This ensures effective heat collection and retention even under extreme cold or significant temperature variations.

4. Smart connectivity, energy efficiency and productivity

The system features an integrated high-precision temperature sensor and intelligent control unit for real-time operational monitoring. This smart system seamlessly interfaces with the building energy management platform, dynamically adjusting heat collection power based on energy demand and environmental conditions to achieve optimal performance. This innovation reduces overall O&M costs by over 35%, while enhancing management efficiency and energy cost-effectiveness.

III. Core Structural Technologies

1. High-efficiency battery with stable output

The core power generation unit utilizes high-efficiency single-crystal N-type TOPCon solar cells with a multi-busbar design, delivering exceptional photoelectric conversion efficiency. Featuring a low temperature coefficient of peak power, it maintains stable performance even under high-temperature conditions, ensuring reliable and consistent power output for extended operation.

2. Constant Temperature Design for Enhanced Efficiency

The collector components feature a scientifically designed uniform temperature flow channel. Using high-purity aluminum plates as the heat transfer substrate, the optimized internal flow channel layout ensures the temperature uniformity of the heated surface remains within an extremely narrow ±1℃ range. This not only enhances heat collection efficiency but also indirectly improves power generation and long-term system reliability by reducing the risk of localized hot spots in the solar cells.

3. High-transparency cover plate to reduce heat loss

The high-transmittance cover plate on the front ensures sufficient light incidence to maintain high power generation, while working in tandem with the internal structure to form an effective air insulation layer. This is one of the key technologies that reduce 70% of the front's thermal loss.

4. Robust protection and long-term durability

The component's frame is crafted from anodized 6063-T5 high-strength aluminum alloy, boasting a tensile strength of 180MPa and exceptional corrosion resistance. When paired with weather-resistant sealing compound, the product achieves IP65 protection, effectively shielding against wind and rain while ensuring long-term durability in harsh outdoor conditions.

IV. Application Scenarios

This product is widely applicable to various scenarios requiring thermoelectric composite applications:

Commercial and public buildings: providing domestic hot water for offices, hotels, schools, etc.

Leisure fitness facilities: Used for heating and maintaining pool water.

Heating system: Coupled with air-source or ground-source heat pump systems to provide heating for buildings.

Regional Energy: Designed for district heating and cross-season thermal storage systems, it enables efficient solar energy utilization across time and space.

V. Why Choose SOLETKS?

The company possesses a comprehensive technological framework across the entire solar energy industry chain. It has achieved multiple cutting-edge technological breakthroughs in clean energy applications such as solar and photovoltaic systems, holding over 117 core patents. These patents cover key areas including high-weather-resistant selective absorption coating technology, thermoelectric coupling technology, and flat-plate thermal energy system integration, with most having been successfully commercialized. The company boasts substantial technical expertise and extensive hands-on experience in research projects.

The company has established a 500㎡ flat plate clean heat energy equipment testing platform, equipped with high-end devices such as a spectral analyzer, collector tightness testing platform, IV testing system, and thermal performance testing platform. It is also equipped with internationally leading digital and intelligent production lines, high-efficiency heat transfer automatic welding equipment, and intelligent flat plate collector assembly lines, achieving an automation rate of over 85% in production equipment.

The PVT-T thermoelectric twin module achieves dual solar energy output (electricity and heat) through integrated technology and structural innovation. With its high efficiency, reliability, and intelligent management, it has become the ideal solution for building energy conservation, carbon reduction, and integrated energy utilization.