Ultra-High-Temperature Flat-Plate Collector: A Dedicated Thermal Energy Solution For High-Temperature Demand Scenarios

Ultra-High-Temperature Flat-Plate Collector: A Dedicated Thermal Energy Solution for High-Temperature Demand Scenarios

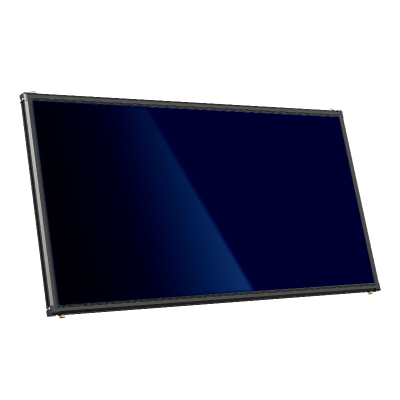

In the fields of industrial production and large-scale heating, "high temperature" is a core prerequisite for ensuring efficiency and effectiveness. Industrial heat utilization requires the stable supply of high-temperature thermal energy above 80°C, even reaching 120°C, to meet the process requirements of production links such as food processing and sterilization, chemical raw material heating, and textile printing and dyeing setting. For centralized heating to cover large areas such as large residential communities and industrial parks, high-temperature heat sources are also necessary to achieve long-distance heat transmission, preventing substandard indoor temperatures at the end due to heat loss along the way. The ultra-high-temperature flat-plate collector is a professional thermal energy equipment tailor-developed for such ultra-high-temperature demand scenarios. With its core capability of breaking through the temperature limit of traditional flat-plate collectors, it has become a key device for solving the pain points of high-temperature demand and promoting the replacement of clean energy.

From the perspective of industrial heat utilization scenarios, the emergence of ultra-high-temperature flat-plate collectors has broken the limitation that traditional clean energy equipment "struggles to reach high temperatures". In the food deep processing industry, some sterilization processes require thermal energy to be stably maintained at 95-105°C. Traditional solar collectors often fail to meet process standards due to large temperature fluctuations and insufficient maximum temperature, forcing enterprises to rely on gas-fired or coal-fired boilers, which not only increases energy consumption costs but also brings environmental pressure. However, through innovative heat collection coating technology and flow channel design, the ultra-high-temperature flat-plate collector can achieve stable heat supply with a maximum temperature of 120°C. It adopts a nano-scale selective absorption coating, which has a solar absorption rate of over 95% and can effectively suppress reverse heat radiation. Combined with fully metal sealed flow channels and high-efficiency heat transfer media, the heat loss rate is reduced to less than 8%. Even in cloudy or low-temperature environments, it can maintain high-temperature output through the heat storage module, fully adapting to links with strict temperature accuracy requirements such as food sterilization and canning processing.

In the chemical and manufacturing industries, ultra-high-temperature flat-plate collectors also demonstrate strong advantages. For example, in rubber product production, raw material preheating requires the continuous supply of high-temperature thermal energy at 100-110°C. Traditional electric heating methods can consume hundreds of kilowatt-hours of electricity per hour, resulting in high operating costs. In contrast, the ultra-high-temperature flat-plate collector uses solar energy as the main energy source, supplemented by a small amount of auxiliary electric heating. It can meet more than 80% of the high-temperature thermal energy demand in a single day. Calculated based on a production line operating for an average of 10 hours per day, it can save hundreds of thousands of yuan in electricity costs annually. At the same time, its industrial-grade pressure resistance and corrosion resistance design enable it to adapt to the complex environment in chemical workshops. The flow channels are made of 316L stainless steel, which can resist corrosion from acid-base gases and has a service life of more than 15 years, significantly reducing equipment replacement and maintenance costs.

In centralized heating scenarios, ultra-high-temperature flat-plate collectors provide an efficient solution for "long-distance, large-scale heating". For centralized heating projects covering multiple residential areas with a total construction area of over one million square meters, traditional low-temperature heat sources can have a heat loss of 5%-8% per kilometer during transmission, leading to low indoor temperatures for end users. However, the ultra-high-temperature flat-plate collector can output high-temperature hot water at 90-100°C. Through high-temperature transmission pipelines, the heat loss is controlled within 3%. Even when the transmission distance exceeds 5 kilometers, the water temperature at the end can still be maintained above 50°C, meeting the residential heating needs. Taking a centralized heating project in an industrial park in northern China as an example, after adopting a composite system of ultra-high-temperature flat-plate collectors and ground-source heat pumps, not only the original coal-fired boilers were replaced, reducing carbon emissions by over 2,000 tons annually, but also the pipeline construction cost was reduced through high-temperature transmission. The heating radius was expanded by 30% compared with the traditional system, and the coverage area was significantly increased.

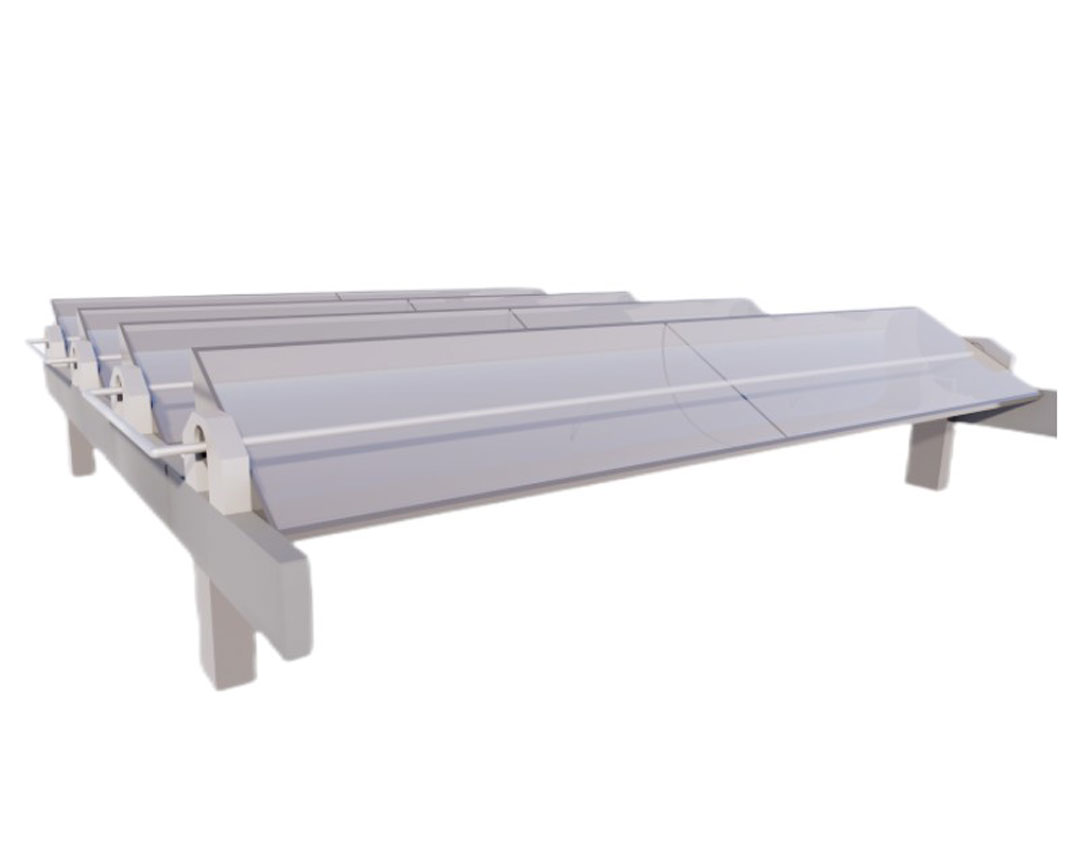

In addition, the ultra-high-temperature flat-plate collector has also been optimized in terms of adaptability and intelligence. Aiming at the installation conditions of different industrial scenarios, it offers a modular design that can be flexibly combined according to factory roof area and site layout. The heat collection area of a single module ranges from 2 square meters to 10 square meters, allowing rapid deployment without large-scale transformation. At the same time, it is equipped with an intelligent temperature control system, which uses a PLC controller to monitor water temperature, flow rate, and light intensity in real time, and automatically adjusts the start and stop of auxiliary heating equipment to ensure stable output of high-temperature thermal energy. Whether it is precise temperature control in industrial production lines or large-scale transmission in centralized heating, the ultra-high-temperature flat-plate collector, with its characteristics of "stable high temperature, energy efficiency, and strong adaptability", provides clean and reliable thermal energy support for ultra-high-temperature demand scenarios, promoting the transformation of the industrial and heating sectors towards green and low-carbon development.